Freely Available British and Irish Public Legal Information

[Home] [Databases] [World Law] [Multidatabase Search] [Help] [Feedback]

Intellectual Property Enterprise Court

You are here: BAILII >> Databases >> Intellectual Property Enterprise Court >> Claydon Yield-O-Meter v Mzuri Ltd & Anor [2021] EWHC 1007 (IPEC) (22 April 2021)

URL: http://www.bailii.org/ew/cases/EWHC/IPEC/2021/1007.html

Cite as: [2021] EWHC 1007 (IPEC)

[New search] [Printable PDF version] [Help]

Neutral Citation Number: [2021] EWHC 1007 (IPEC)

Case No: IP-2018-000045

IN THE HIGH COURT OF JUSTICE

BUSINESS AND PROPERTY COURTS OF ENGLAND AND WALES

INTELLECTUAL PROPERTY ENTERPRISE COURT

Royal Courts of Justice, Rolls Building

Fetter Lane, London, EC4A 1NL

Date: 22/04/2021

Before :

HIS HONOUR JUDGE HACON

- - - - - - - - - - - - - - - - - - - - -

Between :

|

|

CLAYDON YIELD-O-METER LIMITED |

Claimant |

|

|

- and - |

|

|

|

(1) MZURI LIMITED (2) CHRISTOPHER MARTIN LOLE |

Defendants |

|

|

- and –

|

|

|

|

JEFFREY CLAYDON |

Third Party |

- - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - -

Thomas St Quintin (instructed by Nash Matthews LLP) for the Claimant and Third Party

Brian Nicholson QC and David Ivison (instructed by Shakespeare Martineau LLP) for the Defendants

Hearing dates: 24-26 February 2021

- - - - - - - - - - - - - - - - - - - - -

Judgment Approved

Covid-19 Protocol: This judgment was handed down remotely by circulation to the parties’ representatives by email and release to BAILII. The date and time for hand-down is deemed to be 10.30 a.m. on Thursday 22 April 2021.

Judge Hacon :

Introduction

1. In 1701 Jethro Tull invented a seed drill, a mechanical device for sowing seeds with relative precision. It ultimately led to the end of broadcasting seeds by hand in agriculture, pushing forward the agricultural revolution of the time. This case is about modern descendants of Jethro Tull’s seed drill.

2. The Claimant (“Claydon”) is a company based near Newmarket, Suffolk, which makes and sells agricultural machinery. The First Defendant (“Mzuri”) is a company based in Worcestershire which competes in the same market. Claydon alleges that Mzuri has infringed two of its patents.

3. The Second Defendant is the sole director of Mzuri. It is admitted that he is jointly liable for Mzuri’s acts of infringement, if any.

4. The patents in suit (“the Patents”) are UK Patent No. 2 400 296 for an invention entitled “Improved seed drill” (“the 296 Patent”) and European Patent UK No. 2 051 576 (“the 576 Patent”) which claims another invention of the same title.

5. Mzuri counterclaims for revocation of the Patents. Mzuri is the sole counterclaimant and the principal defendant to Claydon’s claim, so hereafter I will refer only to Mzuri.

6. Both Patents were granted to the Third Party (“Mr Claydon”) and thereafter assigned to Claydon. It is common ground that at the date of the claim form, although Claydon held the equitable ownership of the 296 Patent, the legal ownership remained with Mr Claydon. For that reason Mr Claydon was joined as the Third Party by way of being a defendant to Mzuri’s counterclaim. Mr Claydon had a central role as a witness for Claydon but played no active part as Third Party.

The Witnesses

7. Mr Claydon gave evidence of fact on behalf of Claydon. He is the named inventor of both Patents. Mr Claydon was a good witness, giving clear answers. It was suggested in closing that he was obviously not impartial. Perfect impartiality would be a lot to expect from Mr Claydon but it does not follow that the answers he gave - principally directed to an alleged prior use - were inaccurate. Any material impartiality was not obvious.

8. Andrew Scarlett was Claydon’s expert. Dr Scarlett is the director of Scarlett Research Limited, a company which provides research and technical services in the field of agricultural machinery and vehicles. Before starting this business Dr Scarlett spent 16 years at the Silsoe Research Institute where he managed research into and testing of tractor and field machinery. Dr Scarlett was clearly well informed about his field. On the whole, but not invariably, he gave clear answers.

9. Philip Wright was Mzuri’s expert. He is a graduate of Silsoe College. After leaving Silsoe he joined Simba International Limited, a major UK manufacturer of agricultural machinery, rising to become the company’s Technical Director, among other things being responsible for product design and development. Since 2007 Mr Wright has worked in his own consultancy business. Mr Wright gave knowledgeable answers to the questions put to him, again usually but not always clear.

10. There was evidence from Daniel Kelly who is the solicitor with conduct of these proceedings on behalf of the Defendants. His unchallenged evidence concerned a visit to Claydon’s farm at Wickhambrook in Suffolk in support of the Defendants’ case on prior use.

The Patents

The 296 Patent

11. The 296 Patent has a priority date of 29 March 2003. The specification begins by saying that the invention relates to a new method and apparatus for planting seed to produce agricultural crops. The section on the background to the invention explains that it concerns a seed drilling apparatus of the type pulled by a tractor. The invention may be used for sowing in minimally cultivated seed beds, creating conservation tillage in which the soil between the newly sown rows of the new crop is left relatively undisturbed. “Conservation tillage” is, as its name implies, a means of tilling soil in a manner better to conserve it, in particular by reducing soil erosion.

12. The specification indicates on page 7 why this feature is advantageous:

“The invention provides a seed drill and method which is different from anything currently available as it can direct drill or be used as a conventional drill over a wide set of soil conditions.”

13. The indication here is that the inventive concept is related to the disclosure of apparatus that can “direct drill” as well as be used as a conventional drill. As will be seen, “direct drilling” is a term of art but not a precise one. The specification continues on page 7:

“The drill is unique in the way it is set out, how it places the seed and in that it can deal with crop residues in an advantageous manner.

It also only cultivates the soil where the seed is to be planted, thereby creating a conservation tillage, by not disturbing the soil between the rows of crop. This has the advantage that weed seed in the soil between the sown rows will tend not to germinate because the soil between the rows has not been disturbed.”

14. The next passage on page 7-8 provides the reader with an idea of what the 296 Patent means by “direct drilling”:

“When used as a direct drill in straw or stubble it has the advantage of moving the crop residue such as straw and stubble onto the soil between the crop rows. This acts as a mulch, and further enhances weed control with the added advantage that the crop residue retains soil moisture.

This is a considerable advantage on lighter soils that can burn off in dry seasons. However the invention is equally applicable to heavier soils since the local break up and resulting aeration and drainage created by the first tines, below the seed depth, assists in the germination and subsequent growth of the seeds.”

15. “Direct drilling” as that term is used in the 296 Patent thus involves some degree of relocation of the soil in the crop rows, moving it on to the undisturbed rows.

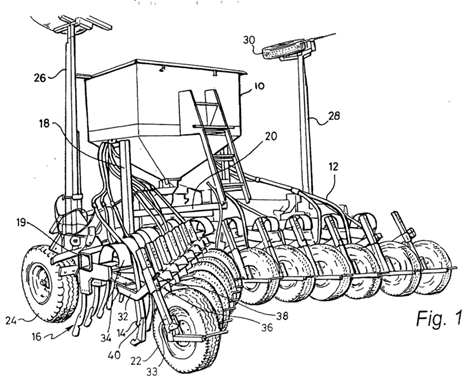

16. Figure 1 is a diagram showing a machine embodying the invention:

17. As can be seen, the machine has parallel units, each of which has seeding tines (14) arranged in a V-shaped array, in front of which are slotter tines (16), which prepare the soil ahead of the seeding tines, arranged in a similar V-shaped array. Seed is fed from the hopper (10) to the seeding tines.

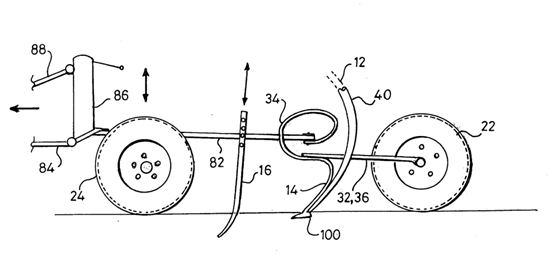

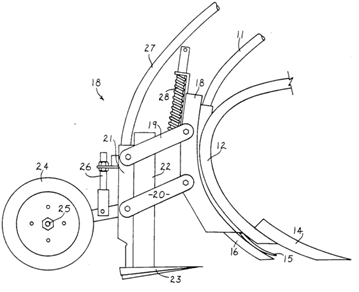

18. Figure 3 is a diagram of one of the units seen from the side:

19. At the centre of the unit is a frame member (82). The height of the frame from the ground is set by adjusting its heigh relative to the depth wheel (24). The height of the slotter tine (16) is adjustable. Behind the slotter tine is the seeding tine (14) with “A-hoe wings” (100) to direct placement of the seeds. Attached to the rear of the frame member is a levelling wheel (22). The levelling wheels firm the soil over the planted seeds, ensuring good contact between the seeds and soil and so promoting germination. Alternative levelling means may be used.

20. From the perspective of Figure 3 the machine moves from right to left. The tractor is thus to the left, linked to connections (84) and (88). As the slotter tines move forward though the soil, they break it to the desired depth. The seeding tines follow behind delivering the seed.

21. The introductory part of the 296 Patent states that the invention may leave undisturbed soil between the newly tilled rows and claim 1 of the 296 Patent has no such requirement. But Claydon alleged infringement of only claim 16 as dependent on claim 8. Claim 8 is a product claim which expressly requires the tines of the apparatus to be aligned in such a way that the soil will only be disturbed in spaced apart linear regions. This was a central feature of the invention relied on at trial.

22. This is claim 8:

“8. Apparatus for cultivating soil and sowing seed comprising:

(a) a frame, adapted in use to be towed by, or attached to the rear of, a tractor,

(b) a first row of tines carried by the frame and spaced apart across the width of the frame,

(c) a second row of tines also carried by the frame and spaced to the rear of the first row in the direction of forward motion of the apparatus when in use, and the second row tines are similarly spaced apart across the width of the frame so that each of the tines in the second row is aligned with one of the tines in the first row whereby in use soil will only be disturbed in spaced apart linear regions determined by the lateral spacing of the tines, and the strips of soil therebetween will not be disturbed,

(d) a hopper means containing seed,

(e) means for feeding seed therefrom down the rear and to the underside of each of the second tines,

(f) soil levelling means carried by the frame and located in alignment with the tines to the rear of the second row of tines (relative to the said forward direction of motion when in use), so that in use as the apparatus moves in a forward direction, soil that has been disturbed by the tines is generally flattened by the passage of the levelling means thereover.

23. This is claim 16:

“16. Apparatus as claimed in any of claims 8 to 15 wherein the tines in the second row include lateral wings which in use lift the disturbed and broken up soil in the trench created by the first tines, as the second tines move therethrough, to allow seed to fall below the lifted soil which, as the second tines continue to move forward, will fall back to cover the seed before the soil is flattened by the following levelling means.”

24. Hereafter references to claim 16 should be taken to mean that claim as dependent on claim 8.

The Skilled Person

25. There was agreement on the pleadings that the skilled person in relation to both Patents is an engineer engaged in the design and manufacture of farming machinery.

The Common General Knowledge in March 2003

The law

26. The law on common general knowledge was considered in some detail by Mr St Quintin because of a criticism raised in Mzuri’s opening skeleton about Dr Scarlett’s evidence. In Dr Scarlett’s second report he said:

“I am told that the Skilled Person lacks inventive capacity, but is deemed to have the common knowledge in the field to which the invention relates, which is referred to has [sic] his “common general knowledge” (“CGK”). However, I am told that that person would not have a particularly high level of base knowledge, and would not necessarily enjoy all the advantages that some people may have in finding information which is not widely circulated.”

27. It was contended by Mzuri that the instruction given to Dr Scarlett that the skilled person would not have a particularly high level of base knowledge was bad in law and that Dr Scarlett’s evidence on the common general knowledge in this case should be treated with caution. Claydon responded with an analysis of the law, contending that there had been no error in Dr Scarlett’s instructions.

28. To my mind the answer is that it depends on what Dr Scarlett took the criterion of a “not…a particularly high level of base knowledge” to mean. If he understood that the skilled person’s common general knowledge did not extend beyond that which would be known to ordinarily competent engineers engaged in the design and manufacture of farming industry, he had the right idea. Should Dr Scarlett’s understanding have been that the common general knowledge of a skilled person was in some way more limited, he did not. If Mzuri’s criticism of Dr Scarlett’s instructions was going to stick, it was necessary to cross-examine Dr Scarlett on this aspect of his understanding of the law. He was asked about it, but no answer was elicited which showed a false understanding on his part.

29. I detected no difference between counsel on the correct principles of the law on the common general knowledge. It is therefore not necessary to explore any aspect of the law in detail and sufficient for me to say that the common general knowledge is the technical background of the skilled person, that is to say the knowledge that such a person will bring to bear when they are reading or otherwise considering the prior art or, as in this case, an alleged prior use. It will be taken to include information readily to hand which the skilled person would have known they could access and which they would have felt the need to access in order properly to consider the prior art. See Idenix Pharmaceuticals Inc v Gilead Sciences Inc [2016] EWCA Civ 1089 at [70]-[72] and Generics (UK) Ltd v Daiichi Pharmaceutical Co Ltd [2009] EWCA Civ 646, at [25]. No geographical dispute arose. Counsel both submitted that the only relevant common general knowledge was that existing at the priority date in the UK.

Direct drilling and Strip-tillage

30. The parties disagreed as to whether a technique called “strip-tillage” formed part of the common general knowledge at the priority date for the 296 Patent in March 2003. Claydon argued that Mzuri’s assertion that it was part of the common general knowledge had not been pleaded could therefore not be part of Mzuri’s case. Mr Nicholson pointed out that it had been pleaded in Mzuri’s schedule to the Amended Reply and Defence to Counterclaim. I can see that it would be easy to miss, but assuming that it matters on the facts of this case, it was pleaded.

31. The dispute about strip-tillage began with the evidence of Dr Scarlett in his first report, in a section in which he described tillage techniques typically employed in the UK before March 2003, which both sides took to mean techniques within the common general knowledge of the skilled person.

32. One of these Dr Scarlett variously termed “zero-tillage”, “no-tillage” and “direct drilling” which, he said, involved no real attempt to create any degree of soil disturbance. He described it by reference to the Oxford English Dictionary

“A method of planting in which soil is not tilled, but instead is planted by insertion of seeds in small slits, weeds being controlled by other means.”

33. There is another technique, which Dr Scarlett called “strip-tillage” and which he described as follows:

“A development of No-Till or Direct Drilling whereby defined linear strips of the field surface are tilled and subsequently planted, leaving undisturbed strips in-between. Depending upon crop inter-row spacing, only 30-50% of soil residues are left on the surface to reduce wind and water erosion. The technique was developed in the US during the late-1990 as a departure from No-Tillage, particularly to suit wide-row (maize and soybean) cropping systems. In these instances tillage is undertaken as a separate operation from seeding, often the former in the autumn and the latter in the spring. The tillage operation may also be combined with deep fertilizer placement. Tilling and seeding are not undertaken as a combined single-pass operation and, before the (2003) priority date, I am unaware of the commercial adoption of this technique in the UK.”

34. Mr Wright thought that the terms “direct drilling” and “strip-tilling” were vague, without well-defined distinctions:

“The variable nature of farming, allied as it is to the weather and conditions prevailing, make a strict definition of most forms of tillage or drilling anyway difficult, and mostly, of little real worth. Thus while the terms ‘direct drilling’, ‘minimum tillage’, ‘strip tillage’ and ‘reduced tillage’ are all used, they have a great deal in common. Strip tilling if this is done in a single pass is a form of ‘direct drilling’, but also embodies ‘reduced’ or ‘minimum’ tillage. Classical ‘direct drilling’ by ‘no tillage’ uses only the opener elements of the drill itself to engage the ground when placing the seed, without leading elements preceding.”

35. Mr Wright was able to be more specific about what the skilled person would have known in the UK in March 2003:

“In conventional UK strip tillage there is an element in the machine (i.e. a disc cutter and/or tine) at the front which tills the strip and a second element (i.e. a coulter) at the back to put the seed in. The first element makes the tilled zone and the second element places the seed exactly into that zone. It could be argued that there is a very little difference between strip tillage and direct drilling as they are used in the UK, as either operation is usually carried out at the same time - there is not generally an autumn tillage pass and spring tillage pass down the strips.”

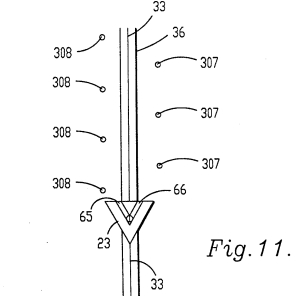

36. This is described by Mr Wright as “one-pass strip-tillage”. In his second report he cited seven publications in support of this forming part of the common general knowledge in March 2003. He was cross-examined on these.

37. The first was what Mr Wright described as a “well-known textbook” called No-tillage Seeding in Conservation Agriculture, Baker et al., 1996, published by the Food and Agriculture Organisation. Mr Wright said that it included a definition of strip-tillage:

“… the practice of tilling a narrow strip ahead of (or with) the drill openers, so the seed is sown into a strip of tilled soil but the soil between the sown rows remains undisturbed.”

38. This seems to be “one-pass strip-tillage” as defined by Mr Wright. It was put to him that this was a specialist book relating to parts of the world where hunger and food security are issues. Mr Wright said that he obtained his copy from a farmer who got it from a bookshop stall at a national show event in the UK. He said that the book could be easily obtained and that its primary author, John Baker, is respected around the world as a leading authority on minimum tillage. Mr St Quintin submitted in closing that the reference to strip-tillage in the Baker book was only in a section said to be of historical interest. I don’t think that is necessarily right. The passage quoted by Mr Wright comes from a list of definitions at the start of the book. The authors introduce the list by saying “Some of these names are listed below with their rationales, for historical interest” (my emphasis). There is no reason to suppose that this includes the definition of “Strip-tillage”.

39. Mr Wright went on to refer to five other publications, of which one was described as a text book. It was Direct Drilling & Reduced Cultivations, Harry Allen, 1981. Chapter 11, entitled “Practical Guidelines - Sugar Beet” describes an experiment in Norfolk in the late 1970s in which alternative approaches to tilling were compared, of which one was strip-tillage”

“Strip-tillage into undisturbed stubble … was compared with [an alternative method]. The test rig consists of a ‘straight-blade’ Rotavator set to cultivate bands 18cm wide and 4-5cm deep, leaving the remaining 32cm between the rows undisturbed. A firming roller is set behind each Rotavator blade. In front of the Rotavator a tine 2cm wide is set at 20cm depth in the centre of each cultivated strip to loosen the soil at depth. This is a most important feature because it moves the soil where the tap roots of the beet will have to grow. Stanhay Mk 2 units are mounted behind the Rotavator so that rigid tine, Rotavator blade, firming roller and Stanhay unit are ‘in line’. The machine drills five rows.”

40. Dr Scarlett confirmed in cross-examination that the Stanhay Mk 2 unit is a seed drill. The machine explained in Allen thus appears to be performing one-pass strip-tillage. It may have been experimental in the UK in the late 1970s, although it is also possible that the experiment resided in the comparison rather than any one technique, but in any event by 1981 one-pass strip-tillage was a matter for discussion in this text book.

41. Dr Scarlett independently referred to the same book by Allen in his second report. He described it as a “comprehensive reference on the subject of direct drilling and reduced cultivations.” He said:

“Whilst Allen reviews commercial direct drills and reduced/minimum tillage drills of the period, which it appears embodied either disc or tine coulters, no mention a made of a direct drill (as cited by Mr Wright) which combines ‘front loosening tines and rear seed delivery components’”.

42. In cross-examination Dr Scarlett said that this was a test rig with a tine at the front, followed by a rotary cultivator as a separate entity, followed by a seed drill which would normally be pulled directly by a tractor. That may be so, but it was a rig for one-pass strip-tillage. It was put directly to Dr Scarlett that his reliance on Allen to show that one-pass strip-tillage was unknown in the UK in March 2003 was not correct. Dr Scarlett did not give a clear answer.

43. I accept Mr Wright’s evidence that the definitions of tillage techniques, including “strip-tillage” are inexact and tend to overlap. To some degree, this bedevils an understanding of what the authors of some of the documents meant when they were discussing one or another technique, not least a document cited by Dr Scarlett by Morris et al, published in 2010.

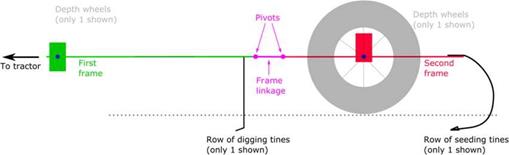

44. I bear in mind that Dr Scarlett did not concede that one-pass strip-tillage was part of the common general knowledge of the skilled person in March 2003. On the other hand, Mr Wright was clear that it was and on this subject Mr Wright was the more convincing. I do not find that the section of any one document referred to by Mr Wright was common general knowledge. But I find that the concept of one-pass strip-tillage, as defined by him, was.

Normal Construction of claim 16 of the 296 Patent

45. I next consider the issues on the normal construction of claim 16 of the 296 Patent (as dependent on claim 8), in the sense explained in Actavis UK Ltd v Eli Lilly and Co [2017] UKSC 48 and Icescape Ltd v Ice-World International BV [2018] EWCA Civ 2219, at [60].

Frame

46. The issue under this head is whether “frame” implies a rigid structure as opposed to one that has articulated members or moveable sections.

47. It is clear that the frame may consist of two or more sub-frames which pivot relative to one another. At page 9 the specification says:

“In order to reduce the overall width of the machine for transport on roads or manoeuvring in restricted spaces, the frame may be constructed from two or more sub-frames which are adapted to be locked in two or more configurations, one of which corresponds to the normal layout for drilling and in another of which the separate parts are folded or swung inwardly, possibly one above the other, to reduce the overall width of the machine.”

48. This could imply that the frame must be rigid in use. On the other hand, figure 11 of the 296 Patent is a diagrammatic side view of a drill embodying the invention highlighting the attachment of the drill to a tractor via a drawbar. The specification says:

“In Fig 11 the frame includes a towbar 130 pivotally jointed at 132 to the front end of the frame 82 and attached at its front end to the tractor drawbar 134.”

49. This is ambiguous in that the frame includes the towbar, yet the towbar is jointed at the front end of the frame. But on balance the language suggests no strict requirement, even in use, that the whole of the frame is rigid.

50. In his first report Mr Wright suggested that “frame” would be understood to mean a rigid structure to which functional components are attached. Mr Wright did not go so far as to say that “frame” is a term of art and Dr Scarlett did not identify it as such.

51. In my view, beyond the frame being a central structure of the drill to which other components are attached, the skilled person would not construe the term to have any strict meaning. It can consist of sub-frames which pivot relative to one another and can include a towbar which pivotally jointed to the rest of the frame, both of these even in use.

Carried by the frame and alignment

52. Claim 8 requires that the first and second row of tines and the soil levelling means are carried by the frame. Mzuri focussed on the purpose of this requirement as set out in claim 8. First, the first and second row of tines are (a) carried by the frame and (b) spaced apart across the width of the frame so that each of the tines in the second row is aligned with one of the tines in the first row. Secondly, the soil levelling means is carried by the frame and located in alignment with the tines to the rear of the second row of tines so that in use soil that has been disturbed by the tines is generally flattened by the passage of the levelling means. It follows, Mzuri argued, that the first and second row of tines will be “carried by the frame” only if such alignment of tines is achieved. Also, the soil levelling means will be “carried by the frame” only if in use the levelling means generally flatten the soil disturbed by the tines.

53. I find this argument persuasive and I agree with it. But it still leaves an ambiguity as to what is meant by alignment. The relevant alignment is of the tines in the first row with those in the second. Claydon argued that the skilled person would understand this to mean alignment in use. I think Claydon is correct about this. Mzuri says, and I have accepted, that the purpose of this aspect of the claim is the key to its interpretation. The claim says that each of the tines in the second row is aligned with one of the tines in the first row “whereby in use soil will be disturbed in spaced apart linear regions determined by the lateral spacing of the tines, and the strips of soil therebetween will not be disturbed” (my italics). What matters is that in use the alignment of the tines will leave strips of undisturbed soil between the soil treated by the tines. It would not matter if, outside use, the tines are not in alignment as required by the claim.

54. As for the soil levelling means being carried by the frame, claim 8 expressly requires that in use this will lead to the soil disturbed by the tines being flattened by the levelling means. In my view, if the soil levelling means are attached to the frame in such manner as to achieve that result, the means are carried by the frame.

Row

55. There was a related argument about the meaning of a first and second “row” of tines. This became bound up with the argument on alignment and carried by the frame and was not pursued by Mzuri as a separate argument.

Feeding seed down the rear and to the underside of each of the tines

56. The drill of claim 8 has a means for feeding seed therefrom down the rear and to the underside of each of the second tines. It must be read in conjunction with claim 16 and its lateral wings. Although raised as a potential issue by Mzuri, it was common ground that the words “to the underside of each of the tines” would not be interpreted meticulously. The skilled person would understand that the seed must be fed close to the underside of the second tines, sufficiently close to achieve the required purpose: that the seeds land in the trench created by the first tine in a place such that it will be covered by the soil lifted by the lateral wings as that soil falls back.

In use lift the disturbed and broken up soil

57. The issue was whether the lifted soil of claim 16 is soil broken up by the first tine. I have no doubt that it is. Each of the tines in the second row moves through the trench created by the corresponding tine in the first row. The claim says that in use the lateral wings lift the disturbed and broken up soil in the trench, not that the wings do the disturbing and breaking up. In my view the words “created by the first tines” refer back both to the trench and the disturbed and broken up soil - both have been created by the first tine. The seed is planted below the lifted soil and the lifted soil then falls back to cover the seed before the soil is flattened.

Mzuri’s Pro-Til

58. The Patents are alleged to be infringed by acts done in respect of Mzuri’s Pro-Til and Pro-Til Select seed drills. There is no relevant difference between the two, so I will refer to them collective as the Pro-Til drills.

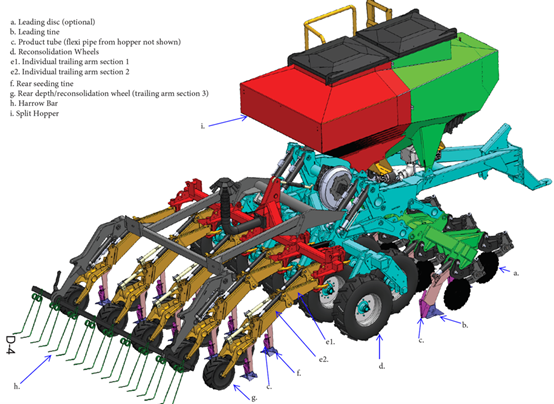

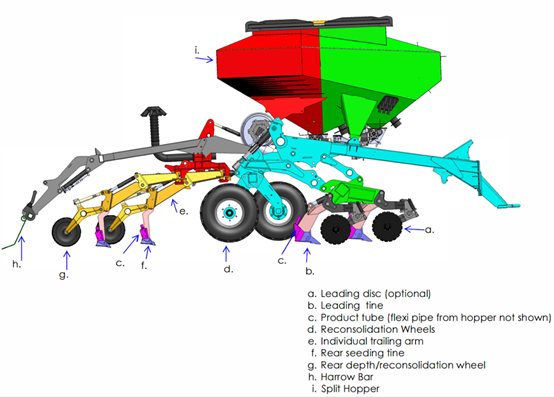

59. Mzuri provided a product and process description (PPD). This is an annotated view of the Pro-Til:

60. The PPD also included a side view:

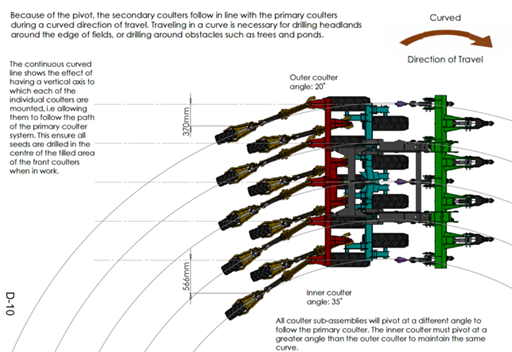

61. The trailing arm assemblies, including the rear seeding tine (f) and the rear depth/reconsolidation wheel (g) (the soil levelling means of claim 8), are pivotally attached to the frame by horizontal pivots. These allow each of the rear tines to follow the trench and disturbed soil created by the corresponding leading tine (b) even when the drill is towed by the tractor along a curved path at the end of a field (the “headland”). This is illustrated in the following diagram from the PPD:

62. On each trailing arm, to the rear of the horizontal pivot, there is a vertical pivot which allows the rear portion of each trailing arm, including the seeding tine and the consolidation wheel, to rise and fall independently and thus adapt independently to variations in the soil surface, such the presence of stones or soil undulations.

Infringement according to the normal construction of claim 16

Frame

63. Mzuri’s first argument on infringement according to the normal construction of claim 8 related to the construction of “frame”. The presence of horizontal pivots connecting trailing arm assemblies in the Pro-Til and vertical pivots along the length of the assemblies means that there is no single rigid frame in use and therefore no frame within the meaning of claim 8 and thus claim 16 as dependent on claim 8. That is not correct on my finding of the correct construction of “frame”.

Carried by the frame and alignment

64. Alternatively, Mzuri argued, the presence of the horizontal pivots will mean that when the Pro-Til is pulled in a curved direction, there will be no alignment between the tines of the first and second row. Therefore the first and second row of tines are not carried by the frame so that they are aligned as required by claim 8.

65. I disagree for two reasons. First, as I have found, the alignment has a purposive meaning: the tines are aligned so that in use soil will be disturbed in spaced apart linear regions determined by the lateral spacing of the tines, and the strips of soil between those treated by the first row of tines will not be disturbed. The horizontal pivots in the trailing arms of the Pro-Til allows for the alignment between the first and second tines to ensure that in use that result is achieved.

66. Secondly, even if “aligned with” in claim 8 means that each tine in the second row must be to the rear of and invariably geometrically in line with a tine in the first row, when the Pro-Til is pulled in a straight line, i.e. most of the time, the tines are aligned according to that meaning. Relevant acts done in relation to the Pro-Til while the tines are thus aligned are acts done in relation to a product which satisfies this element of claim 8.

67. Subject to the validity of the 296 Patent, it has been infringed by Mzuri.

Validity of the 296 Patent

68. The validity of the 296 Patent was challenged by reference to an alleged prior use of the invention by Claydon itself and by reference to United States Patent No. 5,161,472 (“Handy”).

Prior use - the law

69. The starting point for any argument of lack of novelty or inventive step begins with s.2(2) of the Patents Act 1977 and whether at any time before the priority date the invention has been made available to the public. The essential principles governing a claim to prior disclosure of an invention were set out by Aldous J in Lux Traffic Controls Ltd v Pike Signals Ltd [1993] RPC 107, at 133:

“It is settled law that to invalidate a patent a disclosure has to be what has been called an enabling disclosure. That is to say the disclosure has to be such as to enable the public to make or obtain the invention. Further it is settled law that there is no need to prove that anybody actually saw the disclosure provided the relevant disclosure was in public. Thus an anticipating description of a book will invalidate a patent if the book is on the shelf of a library open to the public, whether or not anybody read the book and whether or not it was situated in a dark and dusty corner of the library. If the book is available to the public, then the public have the right to make and use the information in the book without hindrance from a monopoly granted by the State.”

70. In Folding Attic Stairs Ltd v Loft Stairs Co Ltd [2009] EWHC 1221 (Pat), Mr Peter Prescott QC, sitting as a Deputy High Court Judge, was concerned with an alleged disclosure of an invention on private factory premises. He said (at [83]:

“The law must draw the line somewhere, as I have said, and it does so by adopting the rule that inasmuch as the public had a right to be there, they are deemed to have the right to access the information. In the same way, if it is proven that all sorts of members of the public could enter private factory premises, no obligation as to confidentiality being imposed, the law will consider that whatever could be seen there has become part of the state of the art. In those circumstances the law cannot start speculating about who did or did not see the thing.”

71. E. Mishan & Sons Inc v Hozelock Ltd [2019] EWHC 991 (Pat) was an action for infringement of two patents relating to expandable garden hoses. The counterclaim for invalidity of the patents included an allegation of prior use in the course of the inventor’s testing of prototypes in his garden. The argument turned on what the inventor had done and what the public could have seen. The inventor’s evidence, which the judge accepted, was that if he had become aware of anyone watching his testing of the prototype he would either have packed away the equipment and waited until the visitor had left or taken it round to back of his house where it would have been out of sight. Nugee J, as he then was, said:

“[148] It is one thing to say that if the public is given access to information, in whatever guise, that information is made available to the public and it does not matter that no member of the public in fact took up the opportunity: cf Folding Attic Stairs at [86] where Mr Prescott said he understood that the French and German texts of the EPC convey the flavour of "made accessible to the public". Putting a publication in a library makes it accessible to the public, and so available to be read, even if no-one does: it could have been read and the law does not require you to show that it was. Similarly putting a traffic light controller on a public road, or giving contractors access to it, makes it accessible to the public and it could have been observed, and the information that could have been thereby obtained is therefore available to the public, even if no-one stops to look at it; a mat hired to a customer could have been examined, even if it is known for certain that no-one did.

[149] But it is quite another thing to say that the law treats information as available to the public when no member of the public could in fact have accessed it. If it is right as a matter of fact (as I have found that it is) that if any member of the public had tried to observe Mr Berardi in his garden, Mr Berardi would have stopped what he was doing, it seems a misuse of language to say that what he was doing could have been observed, even in theory. If anyone had tried to observe him they would not have seen anything because he would have packed everything up. In other words although any member of the public could have turned up at Skylark Point and stopped to look, had anyone done so, whether a skilled person or anyone else, he would not have been given access to any information. That seems to me to be very different from a publication left in a library for all to read if they choose, or an article left in a public place for all to see if they choose.

[150] This analysis may also provide an answer to Mr Hinchliffe's example of the inventor talking out loud in a public but empty place. I do not need to decide the point but on the view I take it would all depend on what he was doing. It is quite difficult to think of plausible scenarios where this might actually happen in the real world but if, for example, the inventor advertised a public lecture and, even though no-one came, proceeded to give it so it could be recorded for his own purposes, that would on the view I take be an oral disclosure that was accessible, and hence made available, to the public and it would not matter that no-one had in fact turned up. But that would be very different from the inventor talking out loud to himself while taking a walk along a deserted but public footpath over the moors. If in the latter case he would have stopped talking as soon as any member of the public was close enough to hear, I do not think he would have made anything available to the public.

[151] It follows that in the present case the information was not in my judgment in fact ‘made available to the public’ within the meaning of s.2(2) PA 1977.”

72. It was common ground in this case that in a prior user case in which it is said that the invention was made available to the public, even though nobody in fact took advantage of that availability, the information made available is that which would have been either noticed or inferred by a person skilled in the art who, hypothetically, had taken advantage of the access to the invention established on the evidence. I agree. In effect, the hypothesis concerns a skilled person as observer.

73. Mr Nicholson made the further point that for the invention to be enabled, the skilled person need only have been able to discern details of the invention at the level of generality at which they appear in the claim. I agree.

74. As appears from Folding Attic Stairs it must be assumed that the skilled person’s access was limited to that permitted in law; access by trespassing, for instance, is excluded from the hypothesis.

75. Two points were made clear in Mishan that have application to this case. First, where the invention would have been under the control of one or more persons, their likely acts if and when they would have become aware of being observed, and the effect that would have had on the skilled person’s ability to gain information, must be taken into account. Secondly, the information made available will not include anything that would have been acquired in breach of confidence given the relevant circumstances.

76. An additional point of law arose concerning enablement and whether it is to be contemplated that technical equipment would have been used to enhance the detail of what would have been seen. In its skeleton argument Mzuri submitted that there was enablement in this case even if the invention was made available because the skilled person observing it would have had the benefit of binoculars or a video camera. In oral argument Mr Nicholson referred to Folding Attic Stairs in support of this submission.

77. In Folding Attic Stairs the facts of the alleged prior use were that a test version of the invention had been present in the claimant’s factory in Ireland and before the priority date a photographer had been given free access to take photographs at the time of a visit by the Minister for Trade and Tourism. A photograph of the claimant’s Managing Director standing in front of the test unit embodying the invention had been published in the Irish Times. The defendant relied both on the disclosure to the Minister and the photographer, what one might call naked eye disclosure, and the disclosure via the published photograph. It does not seem to have been in dispute that the invention was enabled if the photograph revealed sufficient information about the test unit.

78. Mzuri’s argument in the present case is not analogous since it is not about a real observer never mind one with a video camera. There was no footage constituting the disclosure.

79. I was also referred by Mr Nicholson to PCME Ltd v Goyen Controls Co UK Ltd [1999] FSR 801. This was a patent action concerned with devices used in chimney stacks to monitor the level of dust flowing up the chimney. There was an allegation of prior use of the invention by the sale and delivery of devices in Australia before the priority date. Laddie J found that the devices had been made available as alleged and went on to consider what that prior use disclosed to those in the art. The sale of the devices and their accompanying literature did not describe in any detail how the circuitry in the devices operated, knowledge of which was necessary for the enablement of the invention. Laddie J said that three questions had to be answered: (1) what tests or analyses would it be obvious to carry out on the product, (2) what would be the result of those tests and (3) how would those results be interpreted by the man skilled in the art. In other words, Laddie J was addressing an argument based on the hypothetical reverse engineering of the device. That is not the same as the point at issue here.

80. It seems to me that there is no absolute bar in law to the enablement of an invention by reason of the hypothetical skilled person having gained an understanding of it with the assistance of technical equipment. There are, though, potential difficulties which may prevent such enablement. I give two examples in a contemporary context. If enablement required a phone with a sufficient zoom facility and the evidence showed that at the relevant time and place a member of the public could reasonably have been expected to carry such a phone and use the zoom and could have done so lawfully, then it may be that the hypothesis will go forward on the basis that the information made available included information obtained using the phone, whether seen at the time or recorded and discerned later. On the other hand, it will not be often that evidence will establish that the skilled person would have had a swarm of drones to hand at the relevant time and place and even if they did, use of the swarm may be liable to give rise to issues of privacy and breach of confidence. Both examples assume that the skilled person is a passer-by, in that he or she is not to be taken to have planned the observation in advance.

81. To my mind the evidence in the present case did not sufficiently explore what equipment a member of the public might reasonably have been expected to carry and use to observe Claydon’s prototype without being in breach of an implied obligation of confidence. Brief speculation by Mr Wright was not enough. Nor did it explore what could have been discerned in the prevailing conditions using binoculars or a video camera typically available in August 2002. In my view, therefore, enablement in the present case must be assessed by reference to hypothetical observation with the naked eye.

Prior User - the evidence

82. It was not in dispute that before the priority date of the 296 Patent Claydon tested a prototype of its seed drill which had all the features of claim 16. The prototype was made in Claydon’s farm workshop by Mr Claydon, his brother and a Claydon employee. At the end of August 2002 it was tested in a field on the farm for ten hours, including travel to and from the workshop, split over two days. The issue was whether at any time during those two days the invention of claim 16 was made available to the public.

83. Mzuri’s broad case was that Claydon’s prototype could have been observed from nearby roads and from a footpath to which the public had access, enough to obtain an enabling understanding of the invention.

84. Evidence was given by Mr Claydon as to what happened during the two days of testing the prototype. Daniel Kelly, a solicitor at Shakespeare Martineau, explained his visit to the Claydon farm on 15 October 2019 to take photographs of the field in which it was tested and of its surroundings. The experts gave evidence as to what the skilled person would have been able to determine and infer.

85. In his witness statement Mr Claydon said that he had had experience of patents before the prototype was tested and had learned the hard way that public prior disclosure of his invention would negatively affect his ability to patent it. It was therefore in his mind that he would prevent anyone who happened to be nearby from seeing the prototype. He was in a tractor cab and from that vantage point could see anyone in the vicinity before they could see what was happening in the field. He discussed what to do with his brother, who was present, before the tests began. If anyone had been seen they would have moved away so that this other person would not be close enough to see any relevant detail of the prototype.

86. As it turned out, there was never anyone present other than Mr Claydon and his brother.

87. There is a public footpath that skirts the edge of the field where the testing took place which in 2002 was unmarked and unmaintained. There is and was a hedge about 6 feet high between the footpath and field, but with gaps at three points.

88. By the time of the trial there were two live points. The first was whether the hypothetical observer could have seen the alignment of the tines. The second was whether he or she could have seen strips of undisturbed soil and if so, what would have been deduced from those strips regarding the alignment of the tines. The two points in fact boiled down to one: would the observer have either seen or deduced that each of the tines of the first row was aligned with one of the tines of the second row?

89. In cross-examination it emerged that the point of public access from which an observer would have been best placed to observe the testing of the prototype was a point on the public footpath. Mr Claydon said that the path was very little used in 2002, but that assertion still implied that the public had access to it. Mr Kelly took these photographs of the field from that point in October 2019:

90. It was not suggested by Claydon that the view of the field would have been significantly different in August 2002. Mr Claydon said that he and his brother started the testing of the prototype at 6.30 in the morning in the corner of the field close to this part of the footpath.

91. Mr Claydon was asked to assume that he was driving the tractor pulling the prototype when a person appeared behind him at the point from which the photographs were taken and asked what he would have done if his brother had spotted this person. He said he would have stopped and would have been facing such a person because of the angle he was working the field. If I understood Mr Claydon correctly, he added that if necessary he would have lifted the drill and reversed so that all the observer could have seen was the tractor.

92. Mr Nicholson criticised Mr Claydon for changing his story from that in his witness statement: that he and his brother had rehearsed the strategy of moving away from a stranger who appeared. I find it hard to believe that nearly 20 years later Mr Claydon could accurately say with any certainty what he would have done. No doubt it would have depended on the exact circumstances and the impulse of the moment. That said, his evidence as to what he would have done was not clear. I also note that preventing a member of the public from seeing a prototype seed drill would have been a good deal more difficult than hiding a prototype garden hose in the circumstances of Mishan.

93. Mr Wright said that when the tractor reached a headland it would always have to be lifted out of the soil. The tractor would have slowed or stopped. The prototype would have been lifted well clear of the ground for between 15 and 40 seconds. Since the observer is taken to be a person skilled in the art, he or she would have noticed details that an ordinary member of the public would not. The skilled person would have noted the two rows of tines and would have understood that (a) those in the first row were cultivating tines and those in the second row were seeding tines; and (b) each seeding tine would need to be in line with a cultivating tine. The latter would have been understood because it would be apparent that the drill left in its wake strips of undisturbed soil between strips of disturbed soil. The skilled person would have realised that the seed had been sown in the stripe of disturbed soil created by the corresponding tine of the first row.

94. In his second report Mr Wright referred to a YouTube video which he exhibited to support a further contention that when the drill was turning at the headland near the footpath, the alignment of the tines would be visible when the drill was lifted out of the ground. He repeated that the fairly uniform strips of disturbed and undisturbed soil after passage of the prototype would confirm the alignment of the tines. Mr Wright was not cross-examined on any of this evidence.

95. Dr Scarlett’s accepted in his reports that the presence of two separate sets of tines would undoubtedly have been observed and their respective cultivation and seeding roles probably deduced. But their precise alignment (my emphasis) would not have been easily observed. He said that the observer would have difficulty in determining whether the surface pattern in the field was due to the combined passage of the seeding tines and press wheels or due to the presence of alternate strips of disturbed and undisturbed soil. He added that it would have been necessary to enter the field, scrape away the topsoil and examine what lies underneath.

96. Dr Scarlett was cross-examined on this evidence. He said again that it would be very difficult for the observer to determine what had created the soil pattern left by the prototype without going into the field. However, there followed this passage in the cross-examination:

Q. Just putting observation aside and thinking about the skilled person who is using their skill and experience to think about what you agree they can see, I know you give no reason whatsoever for the skilled person thinking that the machine might be cultivating one strip of land without seeding or fertilising and seeding a parallel strip of land without cultivating it.

A. I have never actually suggested that for one moment. That seemed to be an assertion or a defence that was arrived at in Mr Wright’s reply report but it was not actually a concept that I would have put forward.”

97. It was thus apparently the view of Dr Scarlett that the observer would have known that the prototype caused the seeds to fall into tilled soil as opposed to uncultivated soil. The cross-examination continued:

“Q. I suggest to you that the skilled person thinking about what they are able to see would immediately appreciate that the cultivator tines were cultivating prior to and for the purpose of preparing the ground for seeding. Agreed?

A. What I am actually clearly stating there is the fact that, yes, one would be able to observe and indeed deduce the presence of two separate tines and, earlier in that particular section and indeed in my original report, I have said that the observer would deduce that the rear tines were seeding tines because of the presence of seed delivery tubes to them. That would be deduced and assumed by observation. However, the actual requirement for precise alignment and the presence and existence of precise alignment I do not believe would be deduced. It is not uncommon for a situation whereby two tines may be marginally offset from one another, but would still as you indeed suggest create a tilled area or zone of soil but the precise alignment of them would not be able to be observed from the machine being used in the field, to my mind, or indeed even when it is turning on the headland.”

98. In this evidence Dr Scarlett spoke of there being - as counsel had suggested, he said - a tilled area or zone of soil, presumably as opposed to an untilled zone. I think he must have been talking about strips of tilled and untilled soil. I believe that Dr Scarlett’s real point was that it did not necessarily follow from there being such strips that the tines were precisely aligned; nor could the observer have been able to know that this was the case by looking at the prototype.

99. There is no requirement of precise alignment in claim 16. It is sufficient that they are aligned enough for the seeds fall below the lifted disturbed soil.

100. As for Mr Wright, he had no doubt that the skilled person observing the prototype from the footpath would have been able to see that the soil treated by the prototype had alternate lines of tilled and untilled soil and that therefore the tines in the first and second rows must be aligned. Mr Wright’s evidence on this point had the merit of being easy to follow and making sense.

101. The experts’ evidence on balance suggested to me that an observer of the prototype being tested in August 2002 would have believed the tines in the first and second rows were aligned. There were periods, possibly many, during which it was likely that a skilled person, standing on the footpath at the point where Mr Kelly took his photographs shown above, would have been able to see the prototype in action and been able to deduce from its appearance and from the appearance of soil left in its wake, features of construction of the prototype including all the features of claim 16. If Mr Claydon or his brother had noticed such a person, I do not believe that Mr Claydon could have taken action that would have prevented the skilled person from seeing or inferring each of those features, including the alignment of the tines.

102. Mr Claydon had to test his prototype, nobody saw any of the testing and I entirely understand why he believed that his invention was not publicly disclosed. Unfortunately for him, in law the prototype was made available to the public. Claim 16 of the 296 Patents lacks novelty because of the prior use of the invention in August 2002.

Handy disclosure

103. By the time of closing argument, Mzuri’s pleaded case that Handy anticipated Claim 16 was not pursued. The issue was inventive step. There was no disagreement about the law, inventive step is to be assessed according by reference to the questions set out in Pozzoli Spa v BDMO SA at [23].

104. Handy is a US Patent claiming an invention entitled “Multi-function draft implement”. It explains the need met by the invention:

“Lateral placement of seeds with respect to fertilizer placement can affect yield to a great extent. The placement of seeds directly over or under the fertilizer bands can damage the germinating seed whereas the placement of seeds too far to either side of a fertilizer band doesn’t allow the growing plant to reach the fertilizer.

Accordingly, a need exists for a multifunction draft implement which will be capable of efficient single-pass ground preparation, fertilizing, seeding, and herbicide application functions n which the seed placement is optimized, for depth and lateral placement.”

105. The invention disclosed has a vertical knife-like means (“the banding knife”) for creating a vertical trench in the ground and a horizontal sweeping means (“the planting sweep”) for opening a horizontal swath in the ground and thereby creating a seed-supporting shelf on either side of the vertical trench. Seeds may be deposited on the shelf on either side of the trench. Fertilizer may be placed in the trench and then ground is replaced over the seeds and fertilizer. The planting sweep allows seed placement in parallel paired rows near but not too close to the fertilizer. This may all be done in a single pass. There are also means for depth control.

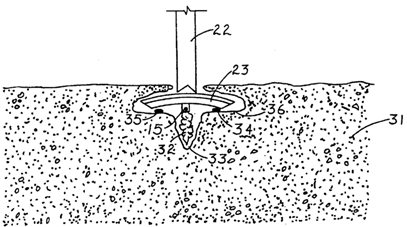

106. An embodiment is shown in Figure 1:

107. In use the drill is pulled from left to right as depicted in the Figure. The banding knife (14) is pulled through the soil and fertilizer is fed into the trench via fertilizer tube (11 and 16) or via an anhydrous conduit (15) for anhydrous fertilizer such as liquid ammonia. It is followed by the planting sweep (23) which plants seeds on the shelves either side of the trench, fed by a conduit (27). The disturbed soil is consolidated by the rear packer wheel (2). The banding knife is supported by an upstanding tool shank (12). The packer wheel and sweep are supported by tubular housing (21) which has a ground deflecting forward portion (22). The tubular housing is connected to a bracket (18) by parallel linkage (19 and 20). The relative depths of the planting sweep and the banding knife can be altered by adjustment of the packer wheel using adjustment means (26). There is a down pressure spring (28) which controls the amount of downward pressure on the packer wheel.

108. A diagrammatic image of a profile created in the soil is shown in Figure 2:

109. Anhydrous fertilizer (32) (in this instance) is deposited from a tube (15) into the trench (33) created by the banding knife. Seeds (34 and 35) are placed on the shelf (36) created by the sweep (23).

110. Figure 11 is a diagrammatic plan view of the seeds (307 and 308) being deposited on the shelf. The trench (33) is between the two halves of the shelf. The sweep (23) has seed planting openings (65 and 66) directed towards the shelf.

111. Claim 1 describes the seed-supporting shelves as being “…in substantially undisturbed soil …”.

Handy and inventive step

112. Handy discloses a seed drill with one tilling and one seeding tine. Claydon accepted in closing submissions that it would have been obvious to use multiple Handy drills attached together in a horizontal row or in a V-shape, towed by a tractor. I will discuss Handy as if it were being implemented in that way.

113. In closing Claydon focussed on aspects of claim 16 of the 296 Patent found in integer (c) of claim 8 and the requirements of claim 16 itself. Claydon argued that Handy did not disclose two of those aspects: first, having a leading tine to disturb and break up the soil in spaced apart rows, i.e. strip-tillage, and secondly, to sow seeds in that disturbed and broken up soil.

114. Mr Wright said in his report that the Handy’s first tine, the banding knife, could vary in depth, width and rake angle, the soil could vary in composition and moisture content and the drill could be used at varying speeds. These variables would alter the shape of the trench produced. Similarly, Handy’s second tine with lateral wings, the sweep, could alter in shape, depth and size. It may be that the first tine creates a wide channel and the second tine would then place seed into soil disturbed by the first tine.

115. Mr Wright was cross-examined on this, during which he gave quite long answers that I find hard to follow even when re-reading the transcript and which I do not find persuasive.

116. Like Dr Scarlett I take the view that Handy is very clear in explaining that the trench created by the first tine is for placement of the fertilizer; the fertilizer should be kept at a distance from the seeds - both experts referred to the known phenomenon of fertilizer “scorching” an emerging seedling. The skilled person reading Handy would understand that the seeds must be sown in a zone separate from the fertilizer, on the shelves to each side of the trench and his or her common general knowledge would reinforce a sense of importance that this separation should be maintained to avoid scorching.

117. In creating the shelves, the second tine will disturb the soil to some degree, although claim 1 suggests that the invention requires the soil to be substantially undisturbed. The important point is that the soil in the zone of the shelves is not the disturbed and broken up soil in the trench created by the first tine. In my view, a skilled person implementing the teaching of Handy would actively seek to avoid that result. I do not believe that it would be obvious to vary the drill disclosed in Handy to create a drill achieving that result.

118. As Dr Scarlett pointed out his first report, there is no mention in Handy of strip-tillage. Dr Scarlett thought that it would not be obvious to use the Handy drill to create strip-tillage but this seems to have been based on the premise that strip-tillage was not common general knowledge. I have found that it was, more specifically that one-pass strip-tillage, as defined by Mr Wright was common general knowledge. Mr Wright’s evidence was that it would have been obvious to apply Handy in such a way as to implement strip-tillage. I was persuaded by Mr Wright in this regard.

119. However, claim 16 of the 296 Patent does not lack inventive step over Handy.

The 576 Patent

120. The 576 Patent claims an invention which is expressly stated to be an improvement on that of the 296 Patent or, more accurately, the invention claimed in PCT Application No. WO 2004/086849 (“the Claydon PCT Application”) which was derived from the 296 Patent. It has an unchallenged priority date of 5 August 2006. The specification also states that the drill of the 576 Patent is for strip-tillage:

“[0003] WO 2004/086849 discloses an improved seed drill which sows seed from seeding tines in rows directly behind digging tines, thus leaving uncultivated land in between the cultivated and seeding tines.”

121. The improvement claimed over the 296 Patent is the ability to set the depth of the two rows of tines independently. The seed drill comprises two frames, each carrying a row of digging tines. The tines on the first frame are digging tines, the tines on the second frame are seeding tines. The second frame has depth wheels which are used to adjust the depth of the seeding tines. The depth of the digging tines is independently adjustable. The specification explains:

“[0007] Thus, the seeding depth can be pre-set to a fixed depth by the position of the depth wheels, whilst the depth of the digging tines can be adjusted independently according to the needs of the soil. Additionally, because the seeding tines are not rigidly connected to the first frame, there is less weight to disturb the seed depth, resulting in less variation in seeding depth.”

122. The function of the tines is identified, beginning with the digging tines:

“[0020] Such tines break the soil to the desired depth, create the drainage, remove compaction and aerate the soil, which is essential for healthy crop growth. Because of their narrow design each such tine cuts through even heavy loam and clay and forms a primary passage or trench for the following seeding tine which carries the seed delivery means for that trench.”

123. Claydon alleges only that claim 1 is infringed, here divided into integers:

“1. An apparatus for cultivating soil and sowing seed, comprising:

(i) (a) a first frame (A) carrying a row of digging tines, adapted in use to be towed by, or attached to the rear of, a tractor,

(ii) (b) a second frame, moveably attached to the first frame, carrying a row of seeding tines,

(iii) each of the seeding tines being aligned with one of the tines on the first frame and spaced therefrom in a direction parallel to the direction of forward motion of the apparatus when in use,

(iv) and comprising depth wheels which in use travel along the surface of the soil,

(v) wherein the seeding depth is governed by the position of the depth wheels relative to the second frame

(vi) and the depth of the digging tines is independently adjustable in relation to the depth of the seeding tines

(vii) and the digging tines each comprise a knife tine and form a primary passage or trench for the following seeding tines, creating drainage, removing compaction and aerating the soil in use.”

Common general knowledge

124. The skilled person is the same as for the 296 Patent. The common general knowledge must be reconsidered.

125. The experts agreed that the common general knowledge would include the belief that the depth at which seeds are to be sown depends on the type of seed and the seeding depth must be consistently correct for that type. There was a need for regular checking of the seed depth.

126. Mr Wright said that it was known to be desirable to adjust the depth of digging to suit different parts of a field. Being able to adjust the digging tines quickly and easily would allow for more efficient operation. He added that adjustment of the depth of the seed drill will be needed if there is a different seed to be sown.

127. Dr Scarlett, responding to this evidence in his second report, said:

“31.3 Whilst it may be undesirable to vary drilling / seeding depth, on Cultivator-type drills (as opposed to Strip-Till drills), which embody separate / preceding cultivation elements which cultivate the entire soil surface prior to the passage of the seeding coulters (e.g. Vӓderstad Rapid, Simba Freeflow), it may indeed be desirable to adjust the cultivating effect and/or depth in different parts of a given field. For instance when drilling field headlands, which have been partly compacted by a tractor turning on them during drilling of the main field, it may be advantageous to increase the cultivating effect / depth of operation of these elements, so that the soil conditions presented to the following seeding coulters more closely represents that found in the main body of the field. In the case of the Vӓderstad Rapid drill, these are the adjustments referred to by Mr Wright in his paragraph 76 and his Exhibit PJW8. However, irrespective of these adjustments and their relative ease on different machines, seeding depth would be held constant.” (original emphasis)

128. This could reasonably be read to mean that while it was undesirable to vary either drilling or seeding depth in cultivator drills, that was not the case in relation to strip-till drills. The use of bold type suggested that the main point Dr Scarlett wished to make was that in relation to cultivators, it may be desirable to vary the cultivating effect and/or depth.

129. In cross-examination Dr Scarlett said that was not what he meant. In this paragraph he was speaking only about cultivator drills and saying nothing at all about strip-till drills. He went on to explain the difference between cultivator and strip-till drills and said that with strip-till drills the depth of the drills would be fixed prior to arrival in the field. Any fine adjustments would be done in relation to seeding depth, not in relation to the digging tine. He also said that such fine adjustments would have little effect on the working depth of the digging tines.

130. In cross-examination Mr Wright agreed with Dr Scarlett to the extent that adjustment of the digging tine does not need to be as precise as that of the seeding tine. It was put to him that even though headland soil may require deeper drilling, it would not matter if that deeper setting were used for the rest of the field. Mr Wright’s response was that this would mean an unnecessary consumption of power when drilling the rest of the field, more fuel consumption and slower travel. The skilled person at the priority date would have known that there was a requirement for better adjustment of the depth of tines.

131. I conclude that the skilled person would have known as part of their common general knowledge that it was desirable to adjust the depth of digging tines and seeding tines independently. Self-evidently, the easier it was to do this the better.

Normal construction of claim 1

Frames, carrying and aligned

132. These three terms are to be construed in a manner similar to the corresponding words in the 296 Patent. Each frame is a structure to which other components of the drill are attached and which may consist of sub-frames which pivot relative to one another.

133. The frames each carry a row of tines which are aligned. There is no purposive guide to the meaning of the alignment in claim 1 of this Patent. However the purpose of alignment is the same: the specification states:

“[0006] … the digging tines each comprise a knife tine and form a primary passage or trench for the following seeding tines, …”

134. What matters is that in use the alignment of the tines will be such as to leave strips of undisturbed soil between the soil treated by the tines.

The seeding depth is governed by the position of the depth wheels relative to the second frame

135. The specification explains relationship between the depth wheels and the depth of the seeding tines:

“[0050] During movement, the depth wheels ride on the surface of the soil and, by earlier selection of their position relative to [the second frame], govern the seeding depth of tines.”

136. Mr Wright provided a schematic diagram in his first report to show how this works:

137. The second frame is supported by the depth wheels. The depth of the seeding tines can be adjusted by moving the depth wheels up or down, in the area indicated by the red rectangle.

138. The dispute was about the meaning of the word “govern”. Claydon argued that it encompassed “influenced by”, i.e. that it would be sufficient if the seeding depth is influenced by - among other things - the position of the depth wheels relative to the second frame. I disagree. It was not said that “governed by” is a term of art. As a matter of ordinary English it means to exercise a controlling influence, not just to exercise one influence among other significant influences.

Alleged infringement of the 576 Patent

139. It was common ground that the seeding depth of the Pro-Til is not governed by the position of the wheels relative to the second frame if “governed by” is construed in the way that I have found it to be. No argument of infringement under the doctrine of equivalents was advanced. The 576 Patent is not infringed.

Validity of the 576 Patent

140. Mzuri alleged that the 576 Patent lacks inventive step over (a) the Claydon PCT Application and (b) Handy.

The Claydon PCT Application

141. The content of the Claydon PCT Application is not materially different from the 296 Patent. During the trial the 296 Patent was used as a convenient proxy.

142. The depth of tilling and the seeding depth cannot be independently altered in seed drill of the 296 Patent. Altering one will impose a substantially similar adjustment to the other. Mr Wright’s evidence was that in August 2006 this would have been an obvious disadvantage given the common general knowledge regarding tilling and seed depths I have referred to above.

143. Mr Wright said that there were two obvious ways of ensuring independent adjustment. One was to ensure that the digging tines are connected in such a way that they can be simultaneously raised or lowered independently of the seeding tines. The other was to add an actuator to each digging tine. He said that the former would have been clearly seen as more attractive because it would be cheaper and simpler to maintain. Mr Wright further explained that the natural consequence of the first option was that the digging tines and seeding tines would have to be on different frames with independent means of height adjustment.

144. Dr Scarlett’s response to this was first to agree that the option of using individual activators for each digging tine was so impractical that the skilled person would immediately reject it. That left the first option, the option claimed as the invention of the 576 Patent.

145. Dr Scarlett did not accept that this first option would have been obvious. I quote his reasoning:

“81. Whilst I consider there is certain logic in the reasoning presented by Mr Wright in paragraphs 219 to 226 of his report, I strongly disagree that there is sufficient justification to embark on such a course of action. As previously discussed, I do not consider that the individual, manual ‘Pin & Hole’ adjustment of digging tine working depth (relative to that of the seeding tines), as described by the 214 Application, constituted a problem which required adaptation / redesign because:

i) The relative infrequent nature of the adjustment

ii) The relatively large inter-tine spacing employed and (as a consequence) the limited number of tines which require adjustment on a machine of given working width.

82. The above analysis would appear to be valid because the ‘manual’ ‘Pin & Hole’ adjustment technique continues to be employed successfully on commercial machines today.”

146. Dr Scarlett’s point was that in August 2006 the skilled person would have thought that there was nothing wrong with the means used in the drill of the 296 Patent for adjusting the depth of the tines. So much so, that he or she would not have considered the matter further. In effect, Claydon’s case was that the invention of the 576 Patent lay solely in appreciating that there was a problem to be solved.

147. Like the Boards of Appeal of the European Patent Office, English patent law recognises the possibility that invention may reside in the perception that there is a problem, see Actavis UK Ltd v Novartis AG [2010] EWCA Civ 82, at [35]. But in the way of things, that will seldom be the case. I am not aware of any example in the case law. Nor was Henry Carr J in TQ Delta LLC v ZyXEL Communications Ltd [2019] EWHC 562 (Pat), at [242]-244].

148. The logic of Dr Scarlett’s evidence was that in August 2007 the skilled person believed that the “Pin & Hole” means of adjusting tine depth as used in the 296 Patent was as good as ever it was going to get, ruling out even any consideration of improvement. In cross-examination, however, his evidence was much more qualified:

“The '576 addresses a perceived need in the marketplace at that point in time. I am unable to actually comment on that because I have not undertaken any market research in relation to it. I believe that the subsequent commercial embodiments of the '576 were commercially successful, but I am actually not in possession of evidence to be able to determine whether or not they fulfilled a need in that respect.”

149. I think that in August 2006 the skilled person would have turned their mind to the advantage of having an easier adjustment of the depth of the digging tines on the drill of the 296 Patent and making it independent of the adjustment of the depth of the seeding tines. I accept Mr Wright’s evidence on this. By the common consent of the experts, once the skilled person considered the matter, the answer disclosed in the 576 Patent would have been obvious.

150. Claim 1 of the 576 Patent lacks inventive step over the Claydon PCT Application.

Handy

151. Mr Wright proposed a development of Handy which he said would have been obvious to the skilled person. He drew attention the parallel connectors which link the digging tine and the seeding tine, what Handy calls “parallel linkage” (19 and 20 in the diagram shown above). Mr Wright identified problems with this design. First, the digging tine of the Handy drill would be weak and liable to be bent out of shape. Secondly, the digging tines would have to be custom made. Thirdly, sprung leaf digging tines, commonly used with this type of machine, flex, particularly under high load. The parallel linkage would transfer this flexing motion to the seeding making both oscillate. This would compromise the consistency of drilling depth.

152. A way of avoiding these disadvantages would be to connect the parallel linkage to a strong, rigid and relatively lightweight hollow frame, rather than directly to the digging tine. This would eliminate the foregoing disadvantages and allow the parallel linkage to be moved higher, making the machine less prone to blockages. It would also bring the drill within the scope of claim 1 of the 576 Patent on the construction advanced by Claydon.

153. Dr Scarlett agreed with Mr Wright on the disadvantages identified, but he said that they applied only to one embodiment of Handy. Mr Wright’s proposed amendments would add to the mass and cost of the machine. Moving the parallel linkage up would subject the components to extra stress and require that more robust components were used. Rather than blockages being removed, they may just be moved to a different location. Dr Scarlett agreed that the modifications proposed by Mr Wright would present no technical difficulty, but the skilled person would have seen no practical justification for them.

154. Both experts maintained their evidence in cross-examination, but I found Dr Scarlett to be more convincing on this topic. It would no doubt have been technically straightforward to make adaptations of Handy to arrive at a drill which fell within claim 1 of the 576 Patent. However, I am not persuaded that the skilled person would have been driven to make the particular changes proposed by Mr Wright. I think they would have been obvious only if the destination of a drill within claim 1 had been in the skilled person’s mind.

Conclusion

155. The 296 Patent is invalid. Had it been valid, it would have been infringed. The 576 Patent is not valid, nor was it infringed.