S.I. No. 388/1953 -- Standard Specification (Pressed Steel Rainwater Goods) Order, 1953

|

S.I. No. 388/1953: STANDARD SPECIFICATION (PRESSED STEEL RAINWATER GOODS) ORDER, 1953 |

||||||||||||||||||||||||||

|

STANDARD SPECIFICATION (PRESSED STEEL RAINWATER GOODS) ORDER, 1953 |

||||||||||||||||||||||||||

|

I, SEAN F. LEMASS, Minister for Industry and Commerce, in exercise of the power conferred on me by subsection (3) of section 20 of the Industrial Research and Standards Act, 1946 (No. 25 of 1946), hereby order as follows :-- |

||||||||||||||||||||||||||

|

1. This Order may be cited as the Standard Specification (Pressed Steel Rainwater Goods) Order, 1953. |

||||||||||||||||||||||||||

|

2.--(1) The specification set forth in the Schedule to this Order is hereby declared to be the standard specification for Pressed Steel Rainwater Goods. |

||||||||||||||||||||||||||

|

(2) The said standard specification may be cited as Irish Standard 59 : 1953 or as I.S. 59 : 1953. |

||||||||||||||||||||||||||

|

SCHEDULE |

||||||||||||||||||||||||||

|

SCOPE |

||||||||||||||||||||||||||

|

1. This specification deals with rainwater pipes, gutters, fittings and accessories made from sheet steel and galvanised after fabrication. Two grades of thickness are specified, viz., light grade and medium grade. Light grade rainwater goods are intended for use on sheds, outhouses, etc. Medium grade rainwater goods are intended for use on buildings where greater durability is required. |

||||||||||||||||||||||||||

|

MATERIAL |

||||||||||||||||||||||||||

|

2. The material used in the manufacture of the pipes, gutters, fittings and accessories shall be black mild steel sheet which shall withstand without fracture being bent cold through 180° either by pressure or by blows, until the internal radius is not greater than one and a half times the thickness of the material. |

||||||||||||||||||||||||||

|

WORKMANSHIP |

||||||||||||||||||||||||||

|

3. The finished pipes, gutters, fittings and accessories shall be true and smooth. They shall be in all respects sound and free from imperfections. The ends shall be finished square to the axes. |

||||||||||||||||||||||||||

|

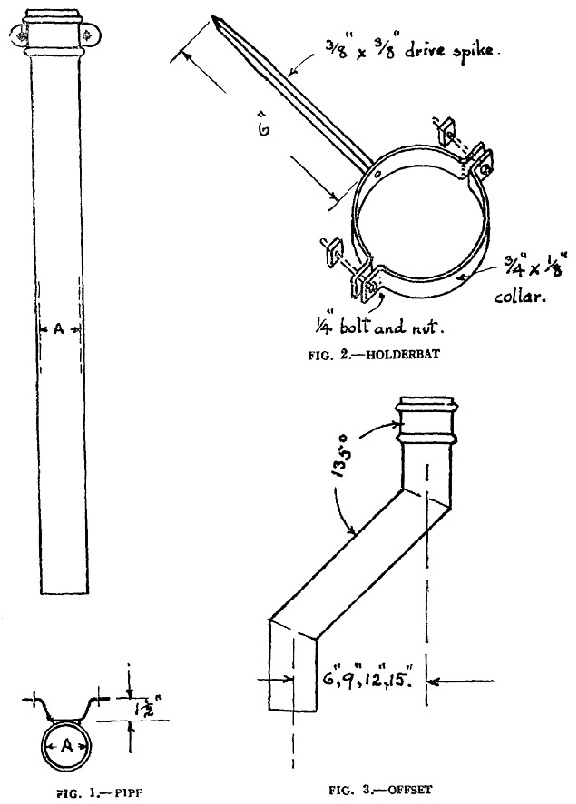

Pipes shall be circular in cross-section. The barrels shall be made from a single piece of material. The sockets may be made from a separate piece joined to the barrel by welding. Pipes and pipe fittings shall be made with a seamed or welded joint. |

||||||||||||||||||||||||||

|

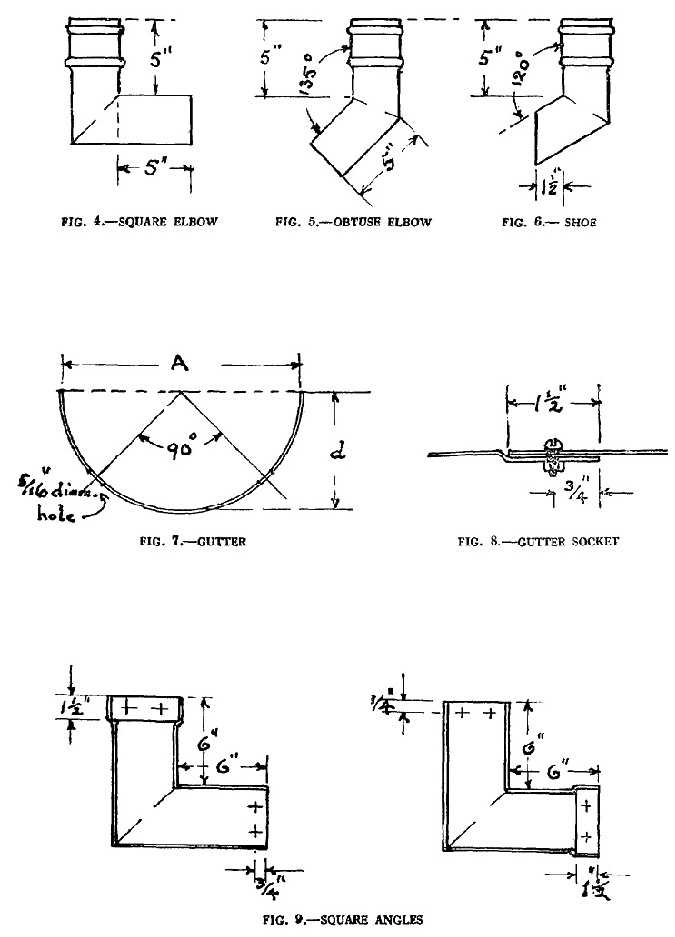

Gutters shall be semi-circular in cross-section and shall be made from a single piece of material. |

||||||||||||||||||||||||||

|

All holes shall be punched before galvanizing. |

||||||||||||||||||||||||||

|

DIMENSIONS OF PIPES AND PIPE FITTINGS |

||||||||||||||||||||||||||

|

4. Nominal Sizes : The nominal sizes of pipes and pipe fittings, expressed in terms of the internal diameter, shall be 2 inches, 2 ½ inches and 3 inches. |

||||||||||||||||||||||||||

|

Diameter : The internal diameter at any point shall not deviate from the nominal size by more than 1/16 inch. |

||||||||||||||||||||||||||

|

Thickness : The thickness of sheet steel used for light grade pipes and pipe fittings shall be 20 B.G. (0·0392 in.) and for medium grade pipes and pipe fittings 14 B.G. (0·0785 in.). |

||||||||||||||||||||||||||

|

Length : The overall lengths of pipes shall be 6 ft. 3 in. and 3 ft. 3 in. A tolerance of ± ¼ in. shall be allowed on the overall length of any pipe, but the average length of a batch of pipes shall be not less than 6 ft. 3 in., or 3 ft. 3 in., as the case may be. |

||||||||||||||||||||||||||

|

Sockets : The depth of sockets shall be 3 in., and the internal diameter shall be such that the spigot can be inserted for the full depth of the socket. The internal diameter of the socket shall be greater than the pipe diameter by 1/8 in., in the case of light grade and 3/16 in., in the case of medium grade pipes and fittings. |

||||||||||||||||||||||||||

|

Ears : The sockets of light grade pipes and fittings shall have ears. The sockets of medium grade pipes and fittings shall be manufactured with and without ears. Ears shall be of steel of not less thickness than that of the metal of the pipe or fitting. They shall be securely attached to the socket before galvanizing and shall be provided with holes of 3/8 in. diameter. The depth of the ear shall be such as to maintain the socket at a distance of 1 ½ in. from a flat surface as indicated in Fig. 1. |

||||||||||||||||||||||||||

|

Holderbats : Holderbats for securing medium grade pipes without ears shall be of mild steel and shall be of the type and dimensions given in Fig. 2. The spike shall be securely riveted to the collar. Each holderbat shall be provided with two galvanized bolts and nuts as shown in the figure. |

||||||||||||||||||||||||||

|

Holderbats shall be galvanized. |

||||||||||||||||||||||||||

|

Offsets, elbows and shoes : Other dimensions of offsets, square elbows, obtuse elbows and shoes shall be as indicated in Figs. 3, 4, 5 and 6. |

||||||||||||||||||||||||||

|

DIMENSIONS OF GUTTERS AND GUTTER FITTINGS |

||||||||||||||||||||||||||

|

5. Nominal Sizes : The nominal sizes of gutters and gutter fittings expressed in terms of the width shall be 3 inches, 3 ½ inches, 4 inches, 4 ½ inches and 5 inches. |

||||||||||||||||||||||||||

|

Width : The width measured between the internal edges at the top shall not deviate from the nominal size at any point by more than 1/16 in. |

||||||||||||||||||||||||||

|

Thickness : The thickness of sheet steel shall be 18 B.G. (0·0495 in.), for light grade gutters and gutter fittings, and 14 B.G. (0·0785 in.), for medium grade gutters and gutter fittings. |

||||||||||||||||||||||||||

|

Length : The overall lengths of gutters shall be 6 ft. and 3 ft. A tolerance of ± ¼ in. shall be allowed on the overall length of any gutter, but the average length of a batch of gutters shall be not less than 6 ft. or 3 ft., as the case may be. |

||||||||||||||||||||||||||

|

Depth : The depth of the gutters at any point, measured as indicated at ` d ' in Fig. 7, shall not deviate from half the nominal size by more than 1/16 in. |

||||||||||||||||||||||||||

|

Sockets : The depth of the sockets as shown in Fig. 8 shall be 1 ½ in. |

||||||||||||||||||||||||||

|

Fixing holes : Both ends of gutters and gutter fittings shall be provided with two fixing holes 5/16 in. in diameter, located as shown in Fig. 7 The distance of the centre of the holes from the end of the socket and from the end of the gutter shall be ¾ in. as shown in Fig. 8. |

||||||||||||||||||||||||||

|

Angles : Other dimensions of square and obtuse angles shall be as indicated in Figs. 9 and 10. |

||||||||||||||||||||||||||

|

Stop-ends : Dimensions of stop-ends shall be as indicated in Fig. 11. |

||||||||||||||||||||||||||

|

Outlets : The dimensions of outlets shall be in accordance with Table 1 and Fig. 12. |

||||||||||||||||||||||||||

|

TABLE 1 |

||||||||||||||||||||||||||

|

Outlets |

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

|

BRACKETS FOR GUTTERS |

||||||||||||||||||||||||||

|

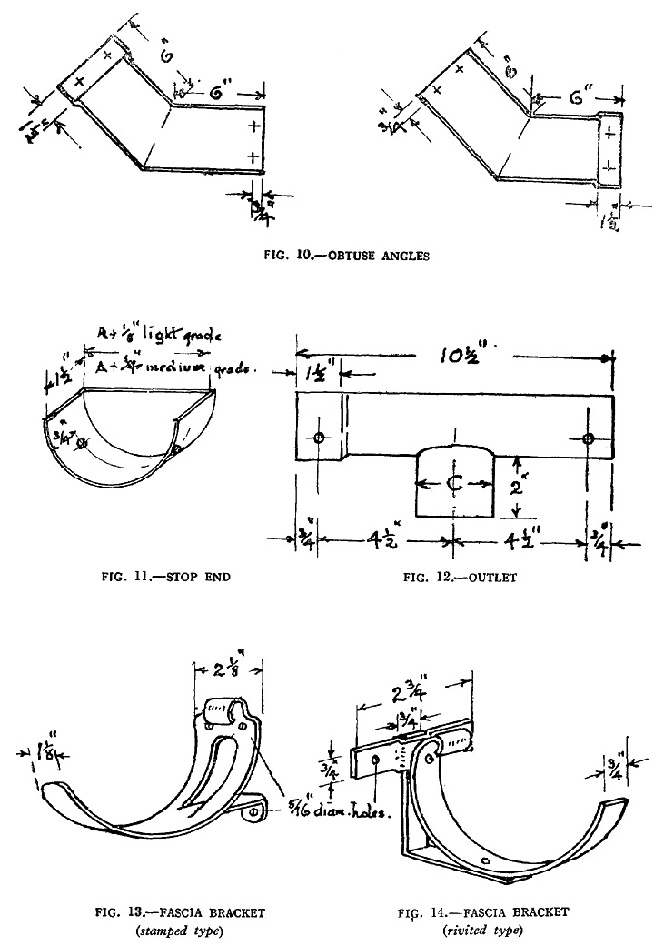

6. Brackets for gutters shall be of the fascia, side rafter, and top rafter types. Fascia brackets shall be either stamped or riveted and the dimensions shall be in accordance with Figs. 13 and 14 respectively. They shall be made of mild steel 1/8 in. thick. |

||||||||||||||||||||||||||

|

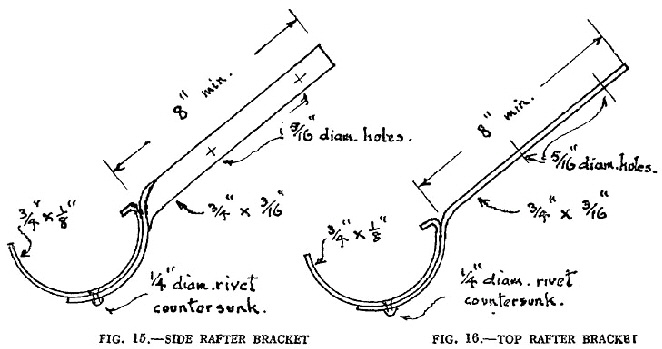

Side and top rafter brackets shall be of mild steel in accordance with Figs. 15 and 16 respectively. |

||||||||||||||||||||||||||

|

Brackets shall be of such a size that they are suitable for carrying the gutter or gutter fittings for which they are required and shall fit closely. All brackets shall be galvanized. |

||||||||||||||||||||||||||

|

BOLTS AND NUTS |

||||||||||||||||||||||||||

|

7. Bolts for jointing gutters and fittings shall be B.S.W. mushroom head bolts ¼ inch in diameter. Bolts and nuts shall be galvanized. |

||||||||||||||||||||||||||

|

GALVANIZING |

||||||||||||||||||||||||||

|

8. Pipes, gutters, fittings and brackets shall be galvanized after fabrication. They shall be thoroughly cleaned of all scale, rust and dirt, by pickling in a bath of dilute acid, and after washing shall be dipped in a bath of molten virgin spelter containing not more than 2 ½ per cent. of impurities, and shall remain therein until the surfaces on removal are completely and evenly coated with firmly adherent spelter free from acid spots and unsightly blemishes or other defects. |

||||||||||||||||||||||||||

|

By agreement between the purchaser and vendor, gutters and fittings may be protected by metal spraying as an alternative to galvanizing. |

||||||||||||||||||||||||||

|

MARKING |

||||||||||||||||||||||||||

|

9. Every pipe, gutter and fitting shall be clearly marked to indicate the grade, the nominal size and the manufacturer's name or mark. |

||||||||||||||||||||||||||

|

FACILITIES FOR INSPECTION |

||||||||||||||||||||||||||

|

10. The purchaser or his representative shall, if he so requires, be given access to the works of the manufacturer at all reasonable times for the purpose of carrying out inspection during manufacture. |

||||||||||||||||||||||||||

|

The manufacturer shall, at his own cost, supply labour and appliances for such inspection as may be carried out on his premises. |

||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||

|

GIVEN under my Official Seal, this 14th day of December, 1953. |

||||||||||||||||||||||||||

|

SEAN F. LEMASS, |

||||||||||||||||||||||||||

|

Minister for Industry and Commerce. |

||||||||||||||||||||||||||

|

|