Freely Available British and Irish Public Legal Information

[Home] [Databases] [World Law] [Multidatabase Search] [Help] [Feedback]

Intellectual Property Enterprise Court

You are here: BAILII >> Databases >> Intellectual Property Enterprise Court >> Quinn Packaging Ltd v Linpac Packaging Ltd & Anor [2019] EWHC 2119 (IPEC) (31 July 2019)

URL: http://www.bailii.org/ew/cases/EWHC/IPEC/2019/2119.html

Cite as: [2019] EWHC 2119 (IPEC)

[New search] [Printable PDF version] [Help]

BUSINESS AND PROPERTY COURTS OF ENGLAND AND WALES

INTELLECTUAL PROPERTY LIST (ChD)

INTELLECTUAL PROPERTY ENTERPRISE COURT

Fetter Lane, London, EC4A 1NL |

||

B e f o r e :

____________________

| QUINN PACKAGING LIMITED |

Claimant |

|

| - and - |

||

| (1) LINPAC PACKAGING LIMITED (2) R. FÆRCH PLAST A/S |

Defendants |

____________________

Geoffrey Pritchard (instructed by Maucher Jenkins) for the First Defendant

Andrew Norris (instructed by TLT LLP) for the Second Defendant

Hearing dates: 18 and 20 June 2019

____________________

Crown Copyright ©

- This action concerns plastic containers of the type typically used in supermarkets for food. Examples are transparent trays with lids in which fresh fruit, fish or meat are stored.

- The claimant ('Quinn') seeks to revoke two patents, each claiming a container of this type. The patents are separately owned, one by the first defendant ('Linpac') and other by the second defendant ('Faerch'). The two patentees are not connected, in fact they are direct competitors in the manufacture and supply of such containers. They were separately represented.

- Anna Edwards-Stuart and David Ivison appeared for Quinn, Geoffrey Pritchard for Linpac and Andrew Norris for Faerch.

- Linpac's patent is UK Patent No. 2 478 028 ('the Linpac Patent'). It has a priority date of 8 January 2010. The specification introduces the invention claimed by stating that it was known to use plastic containers to package, store, transport and display fresh food. Such containers are commonly made of polyethylene terephthalate (PET). The specification states that it is difficult to attach a lidding film (i.e. a lid in the form of a plastic film) to PET and that sealing is sensitive to contamination.

- A known way of dealing with this problem was to make the containers from a three-layer material consisting of PET, an intermediate layer of ethylene vinyl acetate (EVA) and a layer of polyethylene (PE). The lidding film readily attaches to PE, which provides the uppermost surface of the container and so facilitates easy sealing. However, containers made from PET/EVA/PE are less clear than those made from PET, they are more expensive, less recyclable and less easy to manufacture. A particular problem is that the manufacturing process gives rise to 'skeletal waste' – the remaining parts of sheets of the material from which the containers are cut. This cannot be recycled to make clear containers and so becomes an unused environmental hazard.

- The specification explains that the solution to the foregoing problems is to use only PET, or other suitable material which is transparent and recyclable, and to introduce into the design of the container a 'peripheral flange', i.e a horizontal surface extending around the upper periphery of the container. A layer of adhesive is applied to the flange. The lidding film is then pressed on to the flange, sealing the container.

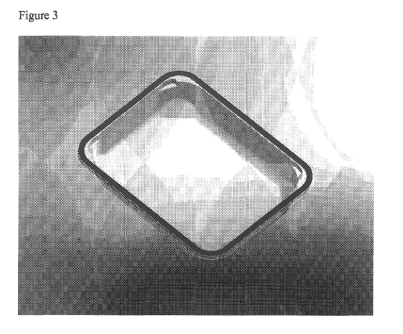

- Figure 3 of the Linpac Patent shows a perspective view of a container made according to the invention. The black line around the rim is the adhesive on the top of the peripheral flange:

- Linpac has applied to amend the patent. At the trial attention was directed to claims 1 and 5 together with 6 and 7 as proposed to be amended:

- The background technology described in the Faerch Patent largely echoes what is stated in the Linpac Patent with a few changes. The Faerch Patent says that a type of PET, amorphous polyethylene terephthalate (APET), is the material of choice for supermarket foodstuff containers. It goes on to describe difficulties in achieving a satisfactory seal with the lidding film using APET. It discusses the multi-layered sheets for making containers mentioned in the Linpac Patent and identifies the problem of skeletal waste associated with multi-layered materials.

- The solution proposed in the Faerch Patent is to make the container from a material having more than one layer, where each of the layers comprises at least 85% APET. As in the Linpac Patent the container has a peripheral flange, here called a 'substantially flat upward facing sealing surface'. A layer of adhesive is applied to the sealing surface so that a seal is formed when the lidding film is applied.

- The filing date is 25 November 2011 and there is no priority date. Argument turned on claims 1 and 7, which are (omitting reference numerals):

- The only significant difference between the two patents is that in the Linpac Patent the container is made of a single layer consisting essentially of any PET, whereas in the Faerch Patent the material which forms the container has at least two layers, both comprising at least 85% APET.

- Charles Shaw is a former Managing Director of Quinn. He was Quinn's expert at the trial. Between 1993 and his retirement in 2014 he held managerial roles in the plastics industry, both in this country and in Spain, becoming Managing Director of Quinn in 2012. Mr Shaw gave clear answers to all question put to him. He was a good witness. He had less direct design experience than the other experts who gave evidence, his views having been formed very largely from a managerial perspective. He was therefore further from the notional skilled person than the other two but I do not believe that this undermined the credibility of his evidence on technical matters.

- Mark Strachan gave expert evidence for Linpac. Since Mr Strachan graduated in 1986 he has worked in the plastics industry in the UK and abroad, with experience in plastics thermoforming, extrusion and injection moulding, this experience including the design of new packaging products. Mr Strachan was a good witness although not always completely clear.

- Thomas Lynggaard is a Senior Materials Scientist at Faerch in Denmark and is one of the two named inventors of the Faerch patent. Mr Lynggaard is a specialist in the design and manufacture of plastic packaging for food and has worked for Faerch since 1999. Mr Lynggaard was also a good witness, giving clear and straightforward answers.

- It was agreed that the skilled person is an engineer engaged in the design and manufacture of plastic packaging for products such as foodstuffs. There was no dispute of significance regarding the skilled person's common general knowledge and it is not necessary for me to set that out in detail save for one matter.

- Unusually, it was common ground that there was a relevant long felt want among those in the plastics industry. Both sides relied on it. It arose from the tendency for the seal between lidding film and plastic containers, especially transparent PET trays for food, to be unreliable. Alternatively, if the seal was improved by using multi-layered plastic to make the containers, the consequence was higher cost and skeletal waste. There was a long felt want for a better solution to sealing lidding film onto containers. All parties agreed that the skilled person would have been aware of that gap in the market.

- Only one item of prior art was cited: Australian Patent No. 638092 ('Ono'). Both patents in suit were alleged to lack inventive step over Ono. The argument over inventive step largely came down to a single point: would a skilled person who read Ono in January 2010 and/or November 2011, knowing of the need for a better sealing solution for plastic food trays, have recognised that Ono provided the answer: the idea of creating a flange around the top periphery of the container and putting a suitable adhesive on it?

- Linpac and Faerch's case was that the long felt want proved just how clever the idea of the peripheral flange was in 2010 and 2011 and that Ono would have led the skilled person away from it. Quinn argued that the skilled person, fully aware of the gap in the market, would have grasped immediately that Ono provided the answer.

- The title of the invention claimed in Ono is 'Method for manufacturing containers provided with a peelable closure'. The specification begins by stating what the invention is about:

- A passage immediately following was much relied on by the defendants:

- Linpac and Faerch argued that this passage sets out a number of 'must haves', attributes which all containers made according to the invention are bound to have. Most relevantly this included an ability to withstand autoclaving under the conditions specified.

- In my view, if the skilled person paused after reading the passages I have quoted, they would not be certain that the 'must haves' (to use the defendants' term) apply to all embodiments of the invention claimed. The words 'more particularly' and 'in particular' in the first paragraph of the second passage could suggest that the qualities of the container which follow, including the 'must haves', are qualities of preferred aspects of the invention, without necessarily being characteristics of every embodiment. The skilled person would read on before deciding which possibility is correct.

- The five claims provide further guidance:

- None of the claims is limited by reference to the container being able to withstand any stated autoclave conditions or indeed that is characterised by any other of the 'must haves' except for easy opening, or peelability, which is required in claim 4. This would have suggested to the skilled person that the invention being disclosed encompassed, but was not limited to, a method for making a container which must withstand autoclaving conditions.

- The skilled person would also note that page 3 of the specification states that the multi-layered sheet employed for producing the containers can be chosen from a number of materials, among them polystyrene and polyester. The latter would be understood to include APET. The experts were agreed that neither polystyrene nor APET would be suitable for autoclaving. Their low glass transition temperature would cause the containers to buckle and melt.

- On page 4 adhesives are listed for use in the Ono method. Mr Lynggaard said in his witness statements that the melting point of these copolymer adhesives were such that they too would melt in an autoclave, causing the sealed tray to open. Mr Strachan was asked in cross-examination whether he agreed with Mr Lynggaard about the unsuitability of the adhesives. He appeared to, although his answer was difficult to follow and suggests that he and counsel may have been at cross-purposes. I accept Mr Lynggaard's evidence on this.

- I have no doubt that the skilled person reading Ono would realise that the specification was proposing, as part of the invention disclosed, materials for the container and adhesives for the seal which would be unsuited to autoclaving. Mr Strachan and Mr Lynggaard each sought to explain this away in cross-examination. Mr Strachan gave a diffuse answer which I did not understand. Mr Lynggaard fell back on the 'must haves' at the start of Ono. I found them both unconvincing in this regard.

- To my mind the skilled person would understand Ono to be teaching a method for making and sealing a container where the container may, but need not be, sterilized by autoclaving after sealing. The materials to make the container and to be used as adhesives would be selected according to whether autoclaving is to be used after the container is made and sealed.

- Claim 1 of Ono requires that the adhesive be 'arranged in proximity to the opening'. As I will discuss further below, the adhesive is added in the form of a 'bead'. The reader is told this on page 5, lines 10-14:

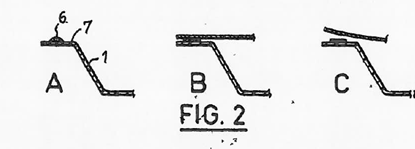

- What this might mean is illustrated by Figure 2:

- In diagram A, a bead of adhesive 6 is deposited on the flange 7 of container 1 ('flange' is the term used in the description of Figure 2). Diagram B shows the production of a seal when the lid is pressed onto the adhesive. Diagram C shows the lid being peeled off, illustrating the claim 4 embodiment in which the lid is peelable.

- The idea of a flange as a platform for adhesive which will be used to seal the container is thus disclosed. The flange is located around the edge portion of the container, i.e. around the periphery.

- Both Mr Pritchard and Mr Norris emphasised that Ono teaches the application of the adhesive in the form of a bead. Claim 1 requires this and there is no teaching of adhesive in any other form. Ono explains, to a limited extent, what is meant by a 'bead' of adhesive in a passage at the bottom of page 3:

- None of the parties suggested that 'bead' is a term of art. I am therefore in as good a position as anyone else to decide what the skilled person would make of it. A key question was the difference, if any, between a bead of adhesive as disclosed in Ono and a layer of adhesive as required by the inventions claimed in both the Linpac and Faerch Patents.

- This was explored during Mr Norris' and Mr Pritchard's respective closing speeches. Mr Pritchard agreed that the bead may be of any shape, but the size of the bead must be such that when squashed during sealing it does not extend substantially across the width of the flange. He went on to say that the skilled person would know from his common general knowledge, and having read Ono, that if the bead, when squashed, extended right across the width of the flange the seal would be too strong and thus not peelable. Mr Norris added that for this reason Ono taught away from applying the adhesive with a roller because that would result in the adhesive extending across the entire width of the flange. In support of this, Mr Pritchard pointed out that Mr Lynggaard had said and Mr Shaw had accepted (as one would expect) that the skilled person would know that the seal strength for any given adhesive is proportional to the surface area of the adhesive once the container is sealed. The gap that Ono fills, Mr Pritchard said, is peelability.

- Ms Edwards-Stuart pointed out the flaw in this explanation of what the skilled person would understand from Ono. As the experts had agreed, the strength of the seal is proportional to the surface area of the adhesive once the container is sealed – in the case of Ono, once the bead is squashed. This has nothing to do with the surface area of the flange. As Ms Edwards-Stuart indicated, the appropriate width of the adhesive might be Xmm to attain a seal which is secure and also peelable; if the flange is also Xmm wide, the squashed adhesive will extend across the entire width of the flange. If the flange is wider than Xmm, it will not.

- In my view the skilled person would understand from Ono that the container is sealed using a bead of adhesive which is applied in the form of one or more continuous closed lines placed on a flange, located around the upper periphery of the container. The shape of the bead is irrelevant. The size of the bead must be such that the one or more lines of adhesive together sufficiently seal the lid to the container for the purpose contemplated. Peelability is in fact optional, but if the preferred peelable embodiment is wanted, the material chosen for the adhesive and the amount applied as a bead must be kept limited to the extent that it allows the lid to be peeled from the container. Ono does not discuss exact amounts, but Mr Lynggaard and Mr Shaw both agreed that a skilled person reading Ono would know how to aim for the correct amount.

- Ono does refer to choosing the type of adhesive to ensure peelability. Immediately following the passage at the bottom of page 3 quoted above, Ono says this:

- When the film is applied, the bead is inevitably squashed – see for example the diagrammatic representation in Figure 2 shown above. The experts were all cross-examined about the difference between a 'bead' and a 'layer' of adhesive. I did not find this helpful. I have already discussed the skilled person's understanding of a bead of adhesive. It was common ground that 'layer' in this context is not a term of art either. It is an ordinary English word which I can interpret without expert evidence. It is not an especially precise term. I have no doubt that the skilled person would agree, if hypothetically asked, that once the lid is applied to the container in the Ono method, squashing the bead of adhesive, there is then a layer of adhesive between the flange of the container and the lid, as shown in Figure 2.

- There was one other point which arose regarding the skilled person's understanding of Ono. In their witness statements Mr Strachan and Mr Lynggaard were both at pains to point out that one of the embodiments of Ono was, to their way of thinking, unworkable. Mr Strachan said that he could see no way of modifying the device to make it work. This was an embodiment in which the bead of thermoweldable material, the adhesive, is applied to the flange during the process of producing the body of the container. It is the embodiment illustrated in Figure 1.

- Mr Strachan and Mr Lynggaard may be right about the impractical nature of the Figure 1 embodiment. But Ono is clear that there is an alternative embodiment in which the adhesive is applied when the cover is sealed, i.e. after the container has been made. I have in mind page 3, lines 15 and 20, which are reflected in claim 1, quoted above ('the thermoweldable bead is injected in proximity to the opening when producing the body of the container or when sealing the cover' (my italics)).

- The main arguments on inventive step were the same in relation to both the Linpac and the Faerch Patent. The defendants said that in order to advance from Ono to either of the patents in suit, the skilled person would have to have done a number of things, i.e. to:

- Of these (c) is the key argument. I will come back to it and meanwhile address the others in turn.

- As I have said, I do not accept that the skilled person reading Ono would understand that the method taught was confined to a method for making containers that can withstand autoclaving.

- The embodiment illustrated in Figure 1 is not the only embodiment disclosed. An alternative is to make the container, then add the adhesive to the flange and apply the lid.

- The skilled person would understand that the bead would become what could properly be described as a 'layer' when the lid is applied on to the adhesive.

- Save for claim 5 of the Linpac Patent, there is no requirement in any of the relevant claims of either patent in suit that the layer be of any particular thickness. Claim 5 claims a thickness from 20 to 100µm, preferably 50µm. In his witness statement Mr Shaw said that a typical seal layer is 35-40µm. This was not challenged. In cross-examination Mr Shaw accepted that there was no encouragement in Ono to go for a layer of either 10µm or 100µm. There is not. But on Mr Shaw's evidence, a skilled reader of Ono would expect to wind up with a layer in the region of 35-40µm once the bead is squashed.

- There is a further point on claim 5. No expert suggested that there was a technical advantage conferred by this range of thickness over adhesives of a different thickness. The seal in Ono need not be peelable, but assuming it is, the experts did not say that this range provided peelability together with a good seal. Claim 5 seems to me to suffer from what is sometimes called 'parametritis', i.e. stipulating that a feature of the alleged invention must be present within a stated range, where the range is entirely arbitrary. In such cases the apparent novelty and inventiveness conferred by the range is illusory, see for example LG Philips LCD Co Ltd v Tatung (UK) Ltd [2006] EWCA Civ 1774; [2007] RPC 21, at [39]. Since there is no expert support for any technical advantage of the range of thickness set out in claim 5, for that reason alone the claim lacks inventive step.

- I turn back to point (c) raised by Mr Pritchard and Mr Norris. For the reasons I have discussed, I take the view that the skilled person would understand that the method disclosed in Ono would include the idea of placing adhesive on a peripheral flange in order to seal the container. He or she would also understand that the Ono method is not limited to containers suitable for autoclaving, or to the Figure 1 embodiment, or to an arrangement other than one with a 'layer' of adhesive, or even to a layer outside the thickness range of 20 to 100µm. The skilled person would therefore have understood that Ono taught a helpful new way to seal lidding film to a container.

- Moreover, even if the Ono method had been limited on one or more of those ways according to the understanding of the skilled person, I do not believe that this would necessarily have undermined Quinn's argument on lack of inventive step.

- It is possible to imagine a disclosure in which the key feature is so bound up with the rest of the product or method that a skilled person reading the disclosure would regard it as being workable only when used as part of the greater whole. On the other hand, it is also possible that a skilled person could recognise a good idea contained within a disclosure which, taken as a whole, is of no interest – for instance because the whole is hopelessly impractical. The gem of a good idea might shine out from the dross of a bad one. This will be a question of fact and degree. Among the relevant facts are whether there is a long felt want for a solution to a problem in the art and whether, primed by this, the skilled person would be likely to spot the solution.

- The idea of putting a layer of adhesive on a peripheral flange located on the upper circumference of a PET container is not buried in the detail of Ono. In my view, to a skilled person, particularly to one with the relevant long felt want in mind, it would be seen as a solution to the problems discussed above, including skeletal waste. To the extent that there are other aspects of the disclosure in Ono which would have been of no interest or seen as impractical, those other aspects would not have distracted attention from the flange with adhesive idea. The skilled person would have understood that the idea could be used both within the context of the Ono method as a whole or outside it.

- In closing Linpac's arguments on claim 1 were condensed into the following two. First Ono would be rejected as a starting point and secondly it was not obvious to use a layer of adhesive as required by claim 1, starting from Ono's teaching of the use of a bead of adhesive.

- For the reasons given, I do not accept either argument. Claim 1 lacks inventive step.

- I have already considered claim 5. It lacks inventive step.

- Linpac admitted that claim 6 as proposed to be amended is not entitled to either of the priority dates of the Linpac Patent. The priority documents for the Linpac Patent were both published before the application for the Linpac Patent was filed. Quinn therefore relied on the second priority document ('Linpac 2A') as prior art.

- Amended claim 6 requires (a) at least one denesting recess located in a denesting area, (b) the denesting area to be relieved relative to the upper surface of the peripheral flange so that (c) the distance between the upper surface of the relieved area and the base of the tray is shorter than the distance between the upper surface of the flange and the base, and (d) the denesting area is devoid of adhesive. Integer (c) means in short that the relieved denesting area is below the flange.

- It was known at the filing date that containers of the type in issue in this case can advantageously be nested, i.e. securely located on top of each other with the base of an upper container sitting within the well of the one below. This promotes cheaper storage and transport. It was also known that easy 'denesting' is an advantage – it is not helpful if nested containers become jammed together and are difficult to separate.

- The skilled person also knew at the filing date that one way of achieving easy denesting was to create a feature in the container, generally in the form of a shoulder projecting from one or more sides, which causes there to be a clearance between the side walls of two containers when they are stacked together.

- Linpac 2A makes no mention of denesting features. Quinn relied only on Figure 3 in Linpac 2A which is identical to Figure 3 of the Linpac Patent, see above.

- Mr Strachan's position in his witness statement was that since the text of Linpac 2A said nothing about denesting, the skilled person would understand the document to disclose nothing about denesting. I do not accept that. Any prior art document must be taken as a whole. All of it is deemed to be considered with interest by the skilled person. If one or more figures in the document would disclose information to the skilled person which is not contradicted or amended by anything said in the text, that information is taken to be disclosed.

- Figure 3 shows the adhesive as a black line along the peripheral flange. One can see that in at least two corners there is an approximately crescent-shaped pale area inward of the black line and a smaller, separate pale area which is apparently a surface slightly below the peripheral flange. The smaller area was said by Quinn to be a denesting recess and this was not challenged. The dispute concerned the larger pale area which Quinn nominated as the denesting area. Both sides agreed that it is not possible to be sure whether the denesting area as shown in Figure 3 is below the peripheral flange or on the same level but without adhesive on its surface.

- Mr Shaw said in his witness statement that having the denesting area lower than the flange would be obvious. He pointed to page 4 of Linpac 2A which says this:

- Mr Shaw said that if a roller is used to apply the adhesive, it would be obvious to offset the denesting area downwards to ensure that it was not coated with adhesive. He was not challenged in cross-examination on this point.

- Mr Strachan said that the skilled person would go for another solution, what he called a bottom denest feature. In cross-examination he conceded that it would technically be no harder to lower the denesting area than to create his bottom denest feature. However, he said that the idea of having a lower denesting area was a brilliant invention.

- So there was a conflict of expert evidence. Mr Strachan thought that a lower denesting area was a brilliant idea, but he gave no reason why, save that he had not thought of it. Mr Shaw said it was obvious and did give a reason. In his view, once the skilled person was prompted with the suggestion of applying adhesive to the flange with a roller, the obvious way of avoiding getting adhesive on the nesting area was to put it at a level lower than the flange. Mr Strachan accepted that there was no technical barrier in the way of doing this. Because Mr Shaw gave a convincing reason for his view, I find his evidence more persuasive. Amended claim 6 would lack inventive step.

- Mr Pritchard conceded in closing that if amended claim 6 was found to be obvious, amended claim 7 would be too.

- Mr Norris said that there was little to add to the argument on inventive step over those advanced in relation to the Linpac Patent. Two differences over Ono were relied on in the written closing submissions. First, the tray must be formed from a material comprising more than one layer where each of those layers comprises at least 85% APET. Secondly, the lid and tray are sealed with a layer (as opposed to a bead) of adhesive.

- I have already discussed the second difference, the alleged invention of going from a bead to a layer.

- The first difference can be split into two: the material of which the container is made must have two or more layers and each of them must be at least 85% APET – they could both be made entirely of APET. In his discussion of the known technology at the priority date of the Faerch Patent Mr Lynggaard said that a preferred material from which trays were made was APET. This first difference therefore boiled down to whether it was obvious to use material consisting of two or more layers made largely of APET.

- In his report Mr Shaw described the practice of recycling PET. He said that such recycling was generally done with APET. He referred to recycled APET as 'RPET'. He explained that the provenance of the APET to be recycled could not reliably be known and it might contain contaminants. Therefore RPET was very commonly used in conjunction with virgin APET in the form of a 3-layer co-extrusion in which a relatively thick layer of RPET is sandwiched between two thinner layers of virgin APET. His evidence was that the making and use of this material would have been entirely routine for the skilled person at the priority date. This was not challenged. In fact, Mr Lynggaard agreed that the skilled person would have known about APET multilayers of virgin and recycled APET although he discussed this in the context of using an anti-block or anti-slip agent to improve denesting.

- It follows that the skilled person at the priority date would have been familiar with the idea of a container as claimed in claim 1 of the Faerch Patent, one made of multi-layered APET, except that it was not known to create a peripheral flange at the top of the tray onto which adhesive is placed. He or she is taken to read Ono. The question is whether Ono would have introduced into the mind of the skilled person the idea of adapting such a tray to have a peripheral flange to which adhesive would be applied. In my view it would, for the reasons discussed in relation to the Linpac Patent. There was no suggestion from anyone that the skilled person would have believed that there was a technical connection between the peripheral flange and multi-layered APET, such that introducing the former required abandoning the latter. I think Mr Norris was right to say that there is little to add to the argument on inventive step over that which applies to the Linpac Patent.

- Claim 1 of the Faerch Patent lacks inventive step.

- Claim 7 is different in that it is directed to a type of adhesive, one that comprises an ethylene copolymer, an ethylene terpolymer or a blend of such polymers, as well as wax.

- Mr Shaw's evidence was that adhesives made from ethylene copolymers and terpolymers with wax were commercially available in 2010. Mr Lynggaard agreed. Mr Lynggaard also said, however, that there was considerable internal testing and discussion within Faerch to come up with the adhesive which Faerch finally used. Ms Edwards-Stuart rightly pointed out that this was evidence of fact from an expert who happened to be one of the named inventors on the Faerch Patent but in the end neither side objected to my taking note of Mr Lynggaard's evidence of fact where I found it to be relevant.

- Mr Lynggaard stated that at the priority date there was no adhesive of the claim 7 type available on the market which afforded sufficient adhesion to both PET and polyethylene and which had sufficiently low viscosity for effective roll coating. He said that it was the lack of these qualities which drove Faerch to develop its own adhesive. Significantly, Mr Lynggaard agreed in cross-examination that Faerch's first choice when embarking on the search for a suitable adhesive had been ethylene vinyl acetate, an ethylene copolymer, with wax. He also said in his witness statement that it took Faerch until version 13 of EVA plus wax to achieve success and that this type of adhesive was not optimised until version 87. The successful recipes were kept confidential.

- Taking this evidence in sum, it does not appear to me that it would have required any invention on the part of the skilled person at the priority date to use an ethylene copolymer with wax as an adhesive. Quite possibly, the skilled person would not have developed a commercially satisfactory adhesive or an adhesive that could easily be applied by roll coating. Those commercial improvements required Fearch's secret recipes. There may have been invention on the part of Faerch in developing those recipes. But claim 7 is not limited to any of them. In my view there was no inventive step in using an adhesive within the broad parameters of claim 7.

- Linpac's application to amend the Linpac Patent pursuant to s.75 of the Patents Act 1977 ('the 1977 Act') is refused because the amended patent would still lack inventive step.

- Quinn also argued that the amended claims do not comply with s.76(3), which provides:

- To explain the argument on extended protection I here set out amended claim 6 marked up to show the proposed deletion and the proposed addition in italics:

- Quinn argued that the deletion of the words 'adjacent a corner of the container' would mean that the amended claim would newly cover embodiments with a denesting recess located otherwise than adjacent a corner of the container. The amendment therefore does not comply with s.76(3)(b).

- I am not convinced by this argument. Although the effect of the amendment to claim 6 is undoubtedly to extend its scope to cover denesting areas which are not adjacent a corner of the container, what matters is whether the amendment would extend the protection conferred by the patent.

- Claim 7 marked up to show the amendments is as follows:

- Claim 7 as granted covers a denesting area which extends partially or completely along the inner periphery of the flange. Quinn's argument works only if it is possible to have a denesting area which is neither adjacent a corner of the container nor extends partially or completely along the inner periphery of the flange. I think that the answer is found in the specification of the Linpac Patent at page 9, lines 19-24:

- The integer 'partially or completely along the inner periphery of the flange' as found in the claims is not limiting but permissive. The denesting area may either lie completely along the inner periphery of the flange or alternatively along part of it, such as adjacent the corners of the tray. That freedom of location is possible in the claims as granted and in the proposed amended claims. Moreover, 'along the inner periphery of the flange' does not imply that the denesting area is level with the flange. It is clear from both the specification and the claims that it may lie at any lower level.

- Linpac barely sought to defend the amendment to claim 6. The point made was that the proposed amendment to claim 7 reintroduces the limitation deleted from claim 6, so amended claim 7 complies with the statute and amended claim 6 can be abandoned. But as I have said, the so-called limitation is not a limitation at all. I do not accept Quinn's first argument on extended protection.

- Quinn had a second argument. It was that amended claims 6 and 7 would newly cover a denesting area which is not free of adhesive. I think that Quinn is right to this extent: on a literal construction of the claims, the protection conferred by the patent would be extended by amendment to encompass a container with a denesting area covered in adhesive. On the other hand, it may be that the skilled person would read into the claim the limitation that a denesting area must be free of adhesive for obvious practical reasons.

- If the permissibility of the amendments had turned solely on this point I would have allowed further submissions on whether there is support for a simple further amendment to cure the difficulty.

- Quinn's argument on added matter depended on the integer 'which extends partially or completely along the inner periphery of the flange' being a limitation. The argument falls away.

- Both the Linpac Patent and the Faerch Patent are invalid because they lack inventive step over Ono. Permission to amend the Linpac Patent is refused since the proposed amended claims would still lack inventive step.

Judge Hacon :

Introduction

The patents

The Linpac Patent

1. A container comprising a base and a continuous side wall extending substantially perpendicular to the base with a peripheral flange formed along the upper, in use, edge of the continuous side wall, wherein the base and the continuous side wall consist essentially of polyethylene terephthalate (PET) wherein a layer of adhesive is located on an upper, in use, surface of the peripheral flange and said layer of adhesive does not extend onto the vertical, in use, surfaces of the continuous side wall and does not extend onto the base wherein the container further comprises a lidding film which may be sealed to the peripheral flange to create a sealed space between the base, continuous side wall and lidding film; and wherein the lidding film is a multi-layer film comprising a seal layer and the seal layer comprises polypropylene (PP) and/or PE.

5. A container according to any preceding claim, wherein the thickness of the layer of adhesive is from 20µm to 100µm, preferably 50µm.

6. A container according to any preceding claim, further comprising at least one denesting recess located in a denesting area, wherein the denesting area is relieved relative to the upper surface of the peripheral flange so that the distance between the upper surface of the relieved area and the base of the tray is shorter than the distance between the upper surface of the flange and the base, and the denesting area is devoid of adhesive.

7. A container according to claim 6, wherein the relieved denesting area is located at the corners of the tray.

The Faerch Patent

1. A container for foodstuff, said container comprising a tray formed from a sheet of material comprising more than one layer, where the material of each of the layers of the formed tray comprises at least 85% of amorphous polyethylene terephthalate, said tray comprising a bottom part, one or more side walls and a peripheral sealing rim at its top, said sealing rim having a substantially flat upward facing sealing surface, wherein, in addition to the material from which the tray is made, the sealing surface is provided with a layer of adhesive along the full circumference of the tray.

7. A container according to any of the preceding claims, wherein the adhesive comprises an ethylene copolymer, an ethylene terpolymer or a blend of such polymers, as well as a wax.

The witnesses

The skilled person and the common general knowledge

The issue on inventive step

Ono

"The present invention relates to a method for manufacturing containers, in particular for food products."

"The invention concerns more particularly the manufacture of containers for packaging foods and in which the package is closed by means produced when manufacturing the container. It concerns in particular containers which may be manually opened and are therefore preferably provided with closures termed peelable closures. Thus, the closing function must ensure:

1) A closure which is fluidtight throughout the life of the food and which must satisfy the following requirements:

transports after the closing stage (packaging line, distribution, …);

sterilization in an autoclave, usually for one hour at 121oC (resistance to this temperature and performance of the adherence…);

storage which may be under tropical conditions for one year (40oC/90% relative humidity), and

sudden variations in temperature due to thermal shocks (changing from -18oC

2) Easy opening with a constant force in use.

3) A closure on a clean surface."

"1. Method for manufacturing a container comprising a body defining an opening, a bead of thermoweldable material arranged in proximity to the opening, and a cover sealed on the bead, characterized in that the thermoweldable bead is injected in proximity to the opening when producing the body of the container or when sealing the cover.

2. Method according to claim 1, characterized in that the thermoweldable material is injected along one or more continuous and closed lines extending around the container.

3. Method according to claim 1 or 2, characterized in that the thermoweldable material is injected onto an edge portion of the container.

4. Container capable of being peeled open, characterized in that it is obtained by the method according to any one of the claims 1 to 3.

5. A method for manufacturing a container and/or a container made thereby substantially as hereinbefore described with reference to the drawings."

"The location of the bead will be chosen to be in a region which is the least likely to be soiled, a region resisting internal pressures, a region permitting a closure of the edge of the container, in particular on the upper or lower surface of the edge portion of the container."

"According to an embodiment of the invention, the thermoweldable material ensuring the sealing of the container is injected onto the container, in particular onto the edge portion of the latter, along one or more continuous and closed lines extending around the container and termed hereafter beads."

"The material of the bead is preferably chosen so as to ensure that the region of peelability: between the surface of the container and the bead, or in the material of the bead ('cohesive rupture'), or between the bead and the closure member."

The arguments on inventive step

(a) ignore the 'must haves' on page 1 of Ono, in particular the requirement that the container must withstand autoclaving;

(b) ignore the only embodiment illustrated in Ono, in Figure 1;

(c) realise that Ono taught something useful about putting adhesive on the peripheral flange;

(d) ignore the fact that Ono taught applying the adhesive in the form of a bead;

(e) migrate from adhesive bead to adhesive layer;

(f) choose a layer thinner than any bead taught in Ono.

The Linpac Patent

Claim 1

Claim 5

Claim 6 as proposed to be amended

"The layer of adhesive may be applied to the upper surface of the peripheral flange by a roller, such as a silicone roller or a heated chrome roller."

Claim 7 as proposed to be amended

The Faerch Patent

Claim 1

Claim 7

Application to amend the Linpac Patent

(1) No amendment of the specification of a patent shall be allowed under section … 75 if it –

(a) results in the specification disclosing additional matter, or

(b) extends the protection conferred by the patent.

Extended protection

A container according to any preceding claim, further comprisingat least one denesting recess, free of adhesive, adjacent a corner of the containerat least one denesting recess located in a denesting area, wherein the denesting area is relieved relative to the upper surface of the peripheral flange so that the distance between the upper surface of the relieved area and the base of the tray is shorter than the distance between the upper surface of the flange and the base, and the denesting area is devoid of adhesive.

A container according toany precedingclaim 6,further comprising a denesting area, free of adhesive, which extends partially or completely along the inner periphery of the flange.wherein the relieved denesting area is located at the corners of the tray.

"… the tray of the present invention may comprise at least one denesting recess located in a denesting area, whereby the denesting area is relieved relative to the upper surface of the flange, i.e. set lower than the flange level by a distance of preferably 1mm. The relieved area extends partially (for example as crescents adjacent the corners of the tray) or completely (i.e. both adjacent the corners of the tray and along the sides of the tray) along the inner periphery of the flange …"

Additional matter

Conclusion