Freely Available British and Irish Public Legal Information

[Home] [Databases] [World Law] [Multidatabase Search] [Help] [Feedback]

England and Wales Court of Appeal (Civil Division) Decisions

You are here: BAILII >> Databases >> England and Wales Court of Appeal (Civil Division) Decisions >> Fiberweb Geosynthetics Ltd v Geofabrics Ltd (Rev 1) [2021] EWCA Civ 854 (11 June 2021)

URL: http://www.bailii.org/ew/cases/EWCA/Civ/2021/854.html

Cite as: [2021] EWCA Civ 854

[New search] [Printable PDF version] [Help]

ON APPEAL FROM

David Stone sitting as a Deputy High Court Judge

Strand, London, WC2A 2LL |

||

B e f o r e :

LORD JUSTICE ARNOLD

and

SIR NICHOLAS PATTEN

____________________

| FIBERWEB GEOSYNTHETICS LIMITED |

Appellant |

|

| - and - |

||

| GEOFABRICS LIMITED |

Respondent |

____________________

Michael Hicks (instructed by Womble Bond Dickinson (UK) LLP) for the Respondent

Hearing date : 27 May 2021

____________________

Crown Copyright ©

- This is an appeal by the Defendant ("Fiberweb") from an order dated 9 April 2020 made by David Stone sitting as a Deputy High Court Judge consequential upon his judgment dated 5 March 2020 [2020] EWHC 444 (Pat) in which he concluded that European Patent (UK) No. 2 430 238 ("the Patent") owned by the Claimant ("Geofabrics") was valid and had been infringed by Fiberweb. Permission to appeal was granted by Floyd LJ on, in essence, two grounds: first, that the judge had erred in his construction of claim 1 of the Patent, and as a result had wrongly found that Fiberweb's Hydrotex 2.0 product ("Hydrotex") fell within the scope of the claim; and secondly, that the judge was wrong to conclude that claim 1 did not lack novelty over International Patent Application No. WO 95/04190 ("Hoare"). It is important to note, for reasons that will appear, that the judge also rejected Fiberweb's alternative contention that claim 1 was obvious over Hoare, and Floyd LJ refused Fiberweb permission to appeal against that conclusion.

- The judge succinctly described the technical background to the dispute as follows:

- The Patent is directed to a synthetic trackbed liner made of a "filtration layer" which restricts the passage of solids material through the liner sandwiched between two "support layers". This is put forward as a solution to the problem of pumping erosion described above.

- At [0001]-[0004] the specification discusses pumping erosion, and the use of a layer of sand as a means of combatting that problem. The additional costs of using sand are noted. At [0005]-[0007] the specification refers to two previous attempts to find a geotextile-based solution to pumping erosion. The first is said to be unsatisfactory for a number of reasons. The second ("Jay") describes a liner consisting of an impermeable membrane and one or two water permeable layers. The specification states at [0007]:

- After a consistory clause corresponding to claim 1 at [0009], the specification states at [0011]:

- Thus the invention does not merely prevent the passage of water into the subgrade, it also uses the source of the problem the cyclical pressure caused by the passage of trains to solve that problem by extracting water from the subgrade without also extracting the fine solids present in clay.

- At [0012] the specification says that the filtration layer should substantially prevent the passage of any solids materials, so as to avoid any significant pumping erosion. At [0013] the specification suggests several types of material that may be suitable for use as the filtration layer. One of these is GORE-TEX, a product commercially available then and now which is widely used for clothing. As the skilled reader would appreciate, this allows perspired water vapour from the body to pass outwards through it, but does not allow liquid water (e.g. rain) to pass inwards through it.

- At [0018] and [0019] the specification described the upper and lower support layers either side of the filtration layer. It explains in [0019] that:

- At [0020] the specification states:

- At [0023] the specification explains:

- At [0051]-[0077] the specification describes embodiments of the invention by reference to 11 Figures. The judge reproduced Figures 1 and 5 in the extract from the judgment quoted above.

- At [0054] the specification states:

- At [0056] the specification states:

- Omitting reference numerals and broken down into integers in the manner agreed between the parties at trial, claim 1 reads as follows:

- It was agreed at trial that the skilled person to whom the Patent was addressed was a professionally qualified geotechnical engineer with several years' post graduate experience and knowledge of railway trackbed design and of the availability, design, manufacture and performance of geosynthetic materials.

- It was agreed at trial that the skilled person's common general knowledge consisted of a list of items of information which the judge set out at [53]. The only items which are relevant to the appeal are the following:

- There is no dispute as to the applicable legal principles. In short, the claim must be interpreted purposively, but without taking into account equivalents, with infringement by equivalents now falling to be separately considered. It is not necessary to elaborate on these principles, however. That is not merely because the principles are not in dispute, but also because the only integer of the claim whose interpretation is in issue is 1.4. This requires that the filtration layer "is normally impermeable to liquid water, that is in the absence of the load of a vehicle acting on the trackbed".

- This integer is unusual in my experience. It is not uncommon for a patent specification to be its own dictionary, in the sense that it contains definitions of terms used in the claims. Indeed, that is true of the specification of the Patent, which states at [11] that "normally impermeable to liquid water" "should be taken to mean that the material is impermeable to liquid water in the absence of the load of a vehicle acting on the trackbed". In the present case, however, that definition has been included within the claim. On the face of it, therefore, there would appear to be little room for argument as to the meaning of integer [1.4]: "normally impermeable to liquid water" means "impermeable to liquid water in the absence of the load of a vehicle acting on the trackbed".

- It is common ground that this definition would not be understood by the skilled reader to require impermeability in the absence of a vehicle at all times and in all circumstances. As the skilled person would appreciate, it would not matter for the purposes of the invention if the filtration layer was permeated by liquid water in exceptional conditions, such as a once-in-ten years flood. This is not because of the use of the word "normally" in the claim, but because the claim must be interpreted purposively.

- This is in essence how the judge construed integer 1.4 at [73], although he placed more weight on the word "normally" than I consider warranted:

- Fiberweb argues that the judge wrongly construed the claim, and that "normally impermeable" means "impermeable under a water pressure equivalent to that of the load of track, sleepers and ballast" which is said in the specification at [0056] to be typically about 2.9kN/m2. Thus Fiberweb contends that the criterion for impermeable is impermeability under a water pressure equivalent to about 2.9kN/m2 (it is common ground that nothing turns on the precise figure). I do not accept this for the following reasons.

- First, that is not how "normally impermeable" is defined in the specification and in the claim. The question of whether any particular material satisfies the definition in the specification and the claim is a separate question, and is a question of fact.

- Secondly, [0056] is part of the discussion of the specific embodiments. It is rarely appropriate to read a limitation into a claim by reference to stray comments in the description of a specific embodiment, but it is clearly illegitimate when (i) the specification and the claim define the meaning of the expression in question and (ii) that definition does not include the criterion contended for by Fiberweb.

- Thirdly, the argument is based on a confusion between the static load on the filtration layer due to the presence of the track, sleepers and ballast on the one hand and the dynamic load exerted during the passage of a train on the other. As the specification makes clear at [0056], the figure of about 2.9kN/m2 is typical of the "static loading due to the ballast 20 and track 14". The same paragraph goes on to refer to the "peak dynamic stress during passage of the train" in contradistinction to the "static loading". There is no dispute that [0023] and [0054] make it clear that it is the dynamic load exerted during the passage of the train which matters for the purposes of the invention, and this is reflected in integer 1.6 of claim 1. Although, as counsel for Geofabrics accepted, [0023] and [0054] are not as pellucid as they might be, they also make it reasonably clear that the reason why it is the dynamic load exerted during the passage of the train that matters is because of its effect on the pressure of the water which is present (i.e. the hydrostatic pressure).

- Fourthly, as the skilled reader would appreciate, this is in accordance with basic physics. As the experts agreed, the static load due to the presence of the track, sleepers and ballast is a load applied during the construction of the track. This force generates an equal and opposite reaction (Newton's Third Law) exerted by the subgrade. Thereafter the system is in equilibrium. Although the result is compression of the liner (which is part of the reason why it needs a degree of robustness as explained at [0019]), this would have no bearing on the hydrostatic pressure of any water present.

- As the experts also agreed, the ballast cannot contain water during and after rainfall because of its open structure, and so the water will run off. Thus (except under flood conditions) the hydrostatic pressure on the liner, and hence the filtration layer, from rainfall will be minimal. By contrast, the passage of a train will cause load dynamically to be applied to the subgrade, causing a transient increase in hydrostatic pressure in water present. This was clearly explained by Fiberweb's expert Professor Ingold in cross-examination:

- Counsel for Fiberweb submitted in oral argument (so far as I can see for the first time) that the judge had incorrectly focussed on impermeability to water above the filtration layer; that what the specification taught the skilled reader was that the filtration layer should be impermeable to water below the filtration layer in the absence of a train, that is to say, the water in the subgrade; and that this meant impermeability under (a water pressure equivalent to) the load of the track, sleepers and ballast. I do not accept that impermeability to water above the filtration layer is irrelevant. On the contrary, the specification is clear that this is an important consideration, because it is necessary to reduce the amount of water which passes through to the subgrade. This includes preventing the return of water which has been squeezed out of the subgrade. Even if one focusses on the water present in the subgrade, however, it remains the case that one must distinguish between the static load imposed by the track, sleepers and ballast and the hydrostatic pressure of any water that may be present.

- Counsel for Fiberweb argued that this interpretation of the claim amounted to disregarding the teaching of the specification at [0011], [0023], [0054] and [0056]. I do not accept this: it merely involves reading the relevant passages with care. Nor does [0020] assist Fiberweb, as counsel suggested.

- Counsel for Fiberweb also argued that it was impermissible to take the physics into account because (i) it was not explained in the specification, (ii) it was not part of the agreed common general knowledge and (iii) the evidence of Prof Ingold had been given in support of an objection of insufficiency which the judge had rejected. I do not accept this either. Although, as already noted, the distinction between the static load due to the track, sleepers and ballast and the hydrostatic pressure of the water is slightly muddled in the specification, it is clear enough. The physics was both elementary and common ground between the experts. The fact that it was not included in the agreed list is neither here nor there: Newton's Third Law was not included in the list, but counsel accepted that the skilled person would know it. The fact that the insufficiency argument based on Prof Ingold's evidence failed does not mean that the common ground between him and Geofabrics' expert Mr Sangster should be disregarded.

- In his skeleton argument, although not in his oral submissions, counsel for Fiberweb also sought to rely upon what the judge had said in the draft judgment circulated to the parties in advance of the final version being handed down. This does not assist Fiberweb. It is the judge's reasoning in the final version that is relevant. That was clarified following a request from counsel for Fiberweb. In any event, regardless of the judge's reasoning, what matters is whether he reached the right conclusion. For the reasons given above, I consider that the judge's construction of the claim was essentially correct.

- As the judge explained at [23]-[25], experiments were carried out to establish the water entry pressure (WEP) of Hydrotex which showed that it has a WEP somewhere between 0.5kPA (equivalent to 0.5kN/m2, or a 50mm head of water) and 2.7kPA (2.7kN/m2, a 280mm head of water). As he recorded, the upshot was that:

- Given this common ground, and the agreement of the experts that a stand of water of greater than 50mm would not be normal, but would only be encountered in exceptional circumstances, it follows that Hydrotex falls within claim 1. Thus the judge was correct to hold that Fiberweb had infringed the Patent if it was valid.

- Hoare is entitled "Improvements in or relating to pavements" and is directed to the same problem as the Patent. Hoare relates to pavements generally, but also refers to railway pavements specifically. Pumping erosion is referred to in [0002] of Hoare, and [0003] of Hoare specifically mentions the problem arising in relation to railway pavements. The disadvantages of using sand to prevent pumping erosion are referred to in [0004] of Hoare. Geotextiles are referred to as a potential solution to prevent pumping erosion in some circumstances.

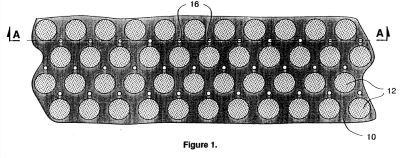

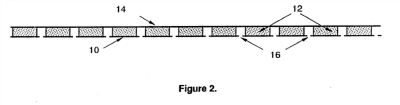

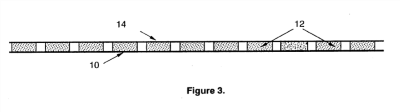

- Paragraph [0006] of Hoare teaches the use of "a multi-layer structure at the interface between the pavement subbase/ballast and the subgrade, said multi-layer structure comprising upper and lower flexible sheet materials and an intermediate load-spreading layer". The "multi-layer structure" is shown in Figures 1, 2 and 3, where Figure 1 is a plan view and Figures 2 and 3 are cross-sections:

- In [0006] of Hoare, the intermediate load-spreading layer is further described as having gaps (16) shown between the disks (12) in Figure 1 so that liquid can pass through. The upper layer (14) is also described as water permeable. The lower layer (10) can be one of three possible types:

- Fiberweb's novelty case relies only on a lower layer of type (b). A type (b) lower layer is further described at [0017] of Hoare:

- There is no dispute that the express cross-reference to GB 1355373 ("Gore") means that the disclosure of Gore is to be taken as part of the disclosure of Hoare. As will appear, however, there is nevertheless a dispute as to precisely how the cross-reference is to be interpreted.

- Gore is a patent relating to the well-known GORE-TEX material referred to above. It is expressly directed to the node-fibril PTFE sheets discussed in Hoare. It is also primarily directed to what it calls "porous materials". Gore also makes clear that the materials it discloses are suitable for use as filter membranes.

- Gore gives 16 examples of materials in accordance with its invention, only one of which is relied upon by Fiberweb in support of its case on lack of novelty, example 10. Example 10 is said to be impermeable at 5psi (35kPA) and permeable above 10psi (70kPA). Example 10 is also expressly taught as being useful for filtration.

- It is common ground that example 10 is the only example in Gore which is identified as being impermeable to any extent. The other examples are either described as being permeable or not clearly identified as being either permeable or impermeable.

- In addition to disclosing and claiming a class of products, Gore also discloses and claims a process for making them.

- There is again no dispute as to the applicable legal principles. In order to establish that claim 1 lacks novelty over Hoare, Fiberweb must show it discloses subject matter which, if performed, would necessarily result in infringement of the Patent: Synthon BV v SmithKline Beecham plc [2006] RPC 10 at [22]. As counsel for Fiberweb pointed out, Lord Hoffmann went on to explain that this does not depend on showing that the author of the prior art intended to make the later invention or described the subject matter in the same way as the later inventor.

- As counsel for Geofabrics pointed out, Lord Hoffmann cited with approval the decision of the Board of Appeal of the European Patent Office in T-396/89 UNION CARBIDE/High tear strength polymers [1992] EPOR 312 at [4.4]:

- As Lord Hoffmann explained at [25]:

- Counsel for Fiberweb also relied upon the principle explained by Jacob LJ in Dr Reddy's Laboratories (UK) Ltd v ELI Lilly and Co Ltd [2009] EWCA Civ 1362, [2010] RPC 9 at [23]-[33] that it is necessary in order for an earlier disclosure to anticipate a later claim that the earlier disclosure contains an "individualised description" of something falling within the later claim.

- The judge rejected Fiberweb's case of lack of novelty for reasons he expressed as follows:

- Counsel for Fiberweb submitted that reason (a) was fallacious, since it merely amounted to saying that Hoare had not disclosed the inventive concept of the Patent, when that was not required for anticipation (although it might be relevant to obviousness). I accept this submission.

- Counsel for Fiberweb submitted that reason (b) involved misreading the disclosure of Hoare at [0017], with its cross-reference to Gore. That was a direction to the reader of Hoare that suitable materials were disclosed in Gore. It necessarily included all the examples, each of which was individually described. Furthermore, if the skilled reader asked himself or herself the question which example would be suitable for use in Hoare's invention, the only example that fitted the bill was example 10. It was immaterial that the material of example 10 was said to be permeable at 10psi, since any material of that kind would be permeable at some WEP, the only question was how high that pressure was.

- Attractively though this argument was presented by counsel for Fiberweb, I do not accept it. As counsel for Geofabrics submitted, it is important to note the purpose for which Hoare cross-refers to Gore. In context, this is to indicate to the reader a way in which to make a "barrier layer formed of an unsintered sheet of polytetrafluoroethylene which is expanded so as to produce a fine microstructure characterised by nodes interconnected by fibrils". That is why Hoare says "see for example" Gore (emphasis added). Furthermore, Hoare does not refer to any of the examples in Gore. Thus it does not direct the reader to use any of the materials disclosed in those examples, as opposed to the general method disclosed in Gore. Accordingly, there is no "individualised description" of the use of the material of example 10 in the context of Hoare (as opposed to in the context of Gore).

- Moreover, as the judge noted, there is no good reason why a skilled person putting Hoare into effect with a type (b) layer would choose the material of example 10 when it is described as being permeable at 10psi, and not as being substantially impermeable. Although anticipation is legally possible in the absence of obviousness, in the present case it is difficult to see how the question whether following the directions of Hoare would inevitably result in a product falling within claim 1 of the Patent could be answered in the affirmative when the answer to the question whether Hoare makes it obvious to produce such a product has been answered in the negative.

- For the reasons given above I would dismiss this appeal.

- I agree.

- I also agree.

Lord Justice Arnold:

Introduction

Technical background

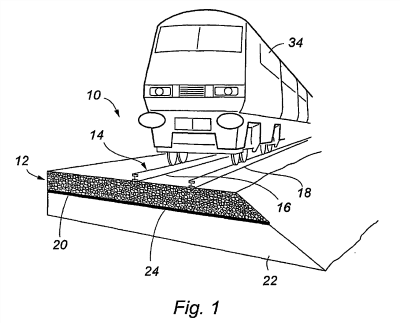

"5. When constructing a railway track, a foundation, called a trackbed, is built, on to which the railway track is laid. Typically, the trackbed comprises a 300mm to 500mm deep layer of ballast, made of graded, crushed rock aggregate. The ballast is laid onto the soil (called the subgrade). By way of example, Figure 1 of the Patent is shown here, with the rails (16 and 18) placed on the ballast (20) which is in turn placed on the subgrade (22):

6. The nature of the subgrade will depend on the local geography. Approximately 10% of the United Kingdom's rail network is laid on a subgrade with a high clay and silt content, such as London Clay or Oxford Clay. Clay subgrades can vary in moisture content when very dry, they can take on the strength of a house brick, but when very wet, they can become a slurry. The pores of the clay can contain water, which can remain in the subgrade even for decades. When it rains, water passes down through the ballast until it reaches the subgrade, and this can, over time, cause a liquid slurry to form on the upper surface of the subgrade.

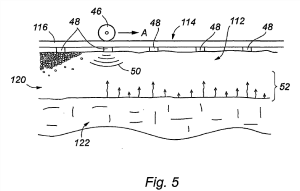

7. When a train passes over a track which has been laid over clay subgrade, a short-lived heavy load is transmitted downwards via the ballast to the subgrade. A train has many wheels: therefore a rapidly repeating heavy load is applied. This will tend to cause the pore water to be squeezed out of the clay. This can lead to pumping erosion: as the pore water is forced out of the subgrade, it carries with it fine particles of clay and silt. Over time, the removal of the clay and silt particles causes erosion to the trackbed, and settling of the track. By way of example, Figure 5 from the Patent is shown here and shows a vertical cross-section through a typical railway track with the cross-section running lengthways down the track. The tracks (116) are placed on sleepers (48), which are placed on ballast (120), which is placed on the subgrade (122). As the train (46) passes over (A), pumping erosion (52) occurs:

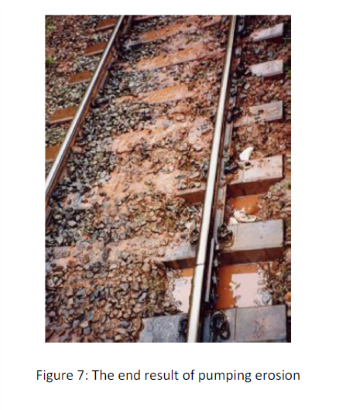

8. The end result of pumping erosion is shown in this photograph taken from the evidence of the Defendant's expert in this case, Professor Terry Ingold. The slurry has migrated up through the ballast, such that it is 'daylighting'.

9. The problem of pumping erosion has long been well known. Traditionally, it was addressed using a 100mm to 150mm layer of sand, placed between the subgrade and the ballast. The sand acted as a filter, slowing the passage of water, and trapping the fine clay and silt particles. But sand had known disadvantages, primarily because it was expensive and inconvenient to lay. Finding a replacement was therefore desirable. Thus, instead of sand, various synthetic trackbed liners have been tried. The Patent, alleged infringement (Hydrotex) and prior art in this case all concern such synthetic liners."

The Patent

"The geocomposite disclosed in [Jay] does not adequately address the problems of pumping erosion, because the impermeable nature of the geomembrane is such that water cannot pass upwardly through it. Passage of a train along the support structure tends to 'squeeze' ground water in the subgrade laterally outwards, carrying solids particles and eroding the track structure."

At [0008] the specification says that it is among the objects of the invention to obviate or mitigate the disadvantages of the prior art.

"Reference is made herein to the at least one filtration layer being of a material which is normally impermeable to liquid water, which should be taken to mean that the material is impermeable to liquid water in the absence of the load of a vehicle acting on the trackbed. Accordingly, it will be understood that the pressure applied to the trackbed liner by the vehicle is sufficient to cause the filtration layer to permit passage of liquid water upwardly therethrough. However, the pores of the filtration layer will be dimensioned so as to restrict the passage of solids materials even under the applied pressure of the vehicle. It will therefore be understood that the load of ballast, sleepers and track located on the liner will generally not be sufficient to cause liquid water to pass through the filtration layer; in other words, the pressure exerted upon the trackbed liner by the ballast, sleepers and track is not sufficiently high to cause liquid water to pass through the filtration layer. This offers the advantage that, once the vehicle has passed (and thus the load exerted upon the liner by the vehicle has been removed), any water which has passed upwardly through the filtration layer cannot return back down through the filtration layer. The water instead flows naturally along an upper surface of the filtration layer (laterally and/or longitudinally of the track), and/or is forced out of the trackbed by subsequent applications of pressure from successive wheels of a vehicle, and/or from a separate vehicle passing along the tracks. Furthermore, this offers the advantage that the volume of liquid water, due to natural rainfall, passing down into the subgrade is restricted as it cannot pass down through the filtration layer."

"The upper and/or lower support layers may have a thickness in the range of about 5 mm to about 20 mm. It will be understood that the thickness will vary according to factors included an expected loading on the liner in use, and the required depth and nature of the ballast. Optionally, the upper support layer may be thicker than the lower support layer, to account for the fact that the upper support layer may be in contact with the ballast, whereas the lower support layer may be in contact with less aggressive materials. The upper and lower support layers may be cushioning layers, and may have a high resilience, to protect the at least one filtration layer from being pierced or otherwise damaged by the ballast."

"The at least one filtration layer may be normally impermeable to liquid water, but may become permeable on application of a sufficiently high pressure to a surface of the filtration layer. The at least one filtration layer may become permeable on application of a pressure of at least about 5kN/ m2, may become permeable on application of a pressure of at least about 10kN/m2, may become permeable on application of a pressure of at least about 15kN/m2, and may become permeable on application of a pressure of at least about 20kN/m2. The at least one filtration layer may become permeable on application of a pressure of in the range of about 10kN/m2 to 100 kN/m2, optionally in the range of about 20kN/m2 to about 100 kN/m2. Permeability may depend upon factors including: the material forming the filtration layer/ composite; dimensions of the filtration layer/composite including pore diameters and/or thickness. Thus the filtration layer may be arranged to become permeable at a certain applied pressure (or within a certain applied pressure range) by appropriate selection of materials and/or dimensioning of the layer/composite. However, tests conducted by the inventors have indicated that the filtration layer of suitable liners typically becomes permeable at an applied pressure of around, or just below, 10kN/m2."

"The vapour permeable material may permit the passage of water vapour but restrict the passage of liquid water. In use and under the load of a vehicle passing along the track, the load exerted upon the trackbed may be sufficiently high as to cause the transmission of water vapour through the vapour permeable material. For example, the downwardly directed load of the vehicle may exert a pressure force on the trackbed which may vaporise liquid water present in the trackbed beneath the vapour permeable material, thereby encouraging passage of water vapour upwardly through the material. Following passage of the water vapour through the vapour permeable material, the water vapour may condense, and may condense on an upper surface of the vapour permeable material and/or on or in the upper support layer and/or in trackbed material located above the upper support layer. The vapour permeable material may prevent return passage of the condensed, liquid water back down through the material. This may occur following passage of the vehicle and thus removal of the applied load. The vapour permeable material may be a porous material and may be microporous. Alternatively, the filtration layer may function, in use and under the applied load of a vehicle, in the fashion described above in relation to the first aspect of the present invention."

"As mentioned above, the filtration layer 30 may be normally impermeable to liquid water. However, in use and under load of a vehicle acting on the trackbed 12, in this case a train 34 (Figure 1), the filtration layer 30 permits passage of liquid water upwardly therethrough but restricts the passage of solids materials, so as to restrict pumping erosion of material located beneath the liner 24 (in this case, the clay subgrade 22). In this fashion, the trackbed liner 24 of the present invention addresses the problem of pumping erosion and without requiring a relatively thick layer of sand to be provided between the ballast 20 and the clay subgrade 22. Furthermore, the liner 24 permits passage of water from the clay subgrade 22 into the ballast 20, which occurs during passage of the train 34 along the track 14, providing a dewatering effect. Water flows from the subgrade 22 because the pressure exerted upon the liner 24 (and thus upon the filtration layer 30) as the train passes over each sleeper of the track 14 is sufficiently high to force liquid water upwardly through the pores 32 of the filtration layer 30 and into the ballast 20. However, following passage of the train 34, when the pressure acting on the filtration layer 30 reduces (and is then due only to the load exerted by the trackbed 12 and track 14), the filtration layer 30 once again becomes impermeable to liquid water. In this fashion, the liquid water which has passed upwardly through the filtration layer 30 cannot return back down through the filtration layer to the subgrade 22, and will drain from an upper surface 36 (Figure 4) of the filtration layer 30."

" the inventors believe that water will be primarily or entirely transmitted through the filtration layer 30 in liquid form, the water transmission occurring due to the increased pressure exerted on the filtration layer when the train 34 passes along the track 14, as will now be described. Typical static loading on the filtration layer (due to the ballast 20 and track 14) would be less than 10kN/m2, and may be approximately 2.9kN/m2 for a typical track 14 having a 300mm depth of ballast 20 of density around 1000kg/m2. The peak vertical dynamic stress during the passage of the train 34 would typically be around 10kN/m2 and may be between 10kN/m2 and 100kN/m2, depending on factors including train axle load, ground stiffness and track 14 type. "

Claim 1

"1. A trackbed liner comprising:

[1.1] an upper support layer;

[1.2] a lower support layer; and

[1.3] at least one filtration layer of a material having a plurality of pores

[1.4] and which is normally impermeable to liquid water, that is in the absence of the load of a vehicle acting on the trackbed,

[1.5] the filtration layer located between the upper and lower support layers;

[1.6] in which the pores of the filtration layer are dimensioned so that, in use and under load of a vehicle acting on the trackbed, the filtration layer

[1.6.1] permits passage of liquid water upwardly therethrough but

[1.6.2] restricts the passage of solids materials, so as to restrict pumping erosion of material located beneath the liner."

The person skilled in the art

Common general knowledge

"(a) The recognised problem of pumping erosion including that it is caused by the passage of a train over subgrade which is wet and which as a result forms a slurry.

...

(e) The fact that geosynthetics can be permeable geotextiles or impermeable geomembranes.

...

(h) Knowledge of the concepts of water entry pressure (WEP), pore size and permeability and how to vary them in geotextiles."

Construction of claim 1

"Considering the Patent through the eyes of the skilled addressee, and applying a purposive construction, in my judgment 'normally impermeable to liquid water, that is in the absence of the load of a vehicle' means what it says in 'normal' conditions, the filtration layer will not allow water to pass through it. At [0011], the Patent sets out the reason for this: so that rainwater, and water which has passed up through the filtration layer, will run off to the sides rather than passing (back) down through the filtration layer into the subgrade. The skilled addressee will appreciate that the product is to be used on a railway track. Those 'normal' conditions are therefore when in use as a geotextile under ballast and above subgrade as part of a railway track. The 'normal' conditions include the weight of the ballast, sleepers and rails (but not a train). They also include the presence of rainwater (including any water that has been permitted to pass upwardly through the filtration layer), but not a flood the experts both accepted that under normal conditions, water would not pool on top of the geotextile in substantial quantities because of the way in which railways are constructed. ... The Patent does not refer to stands of water, but the experts agreed that a stand of water of greater than 50mm would not be normal, because stands of water would only arise in unusual (ie, not 'normal') flood conditions. I do not consider that the skilled addressee would assess permeability from above in light of the pressure applied by the track and ballast. As the Patent sets out at [0056], the load of the track and ballast (but not a train) would be approximately 2.9kN/m2. This is the pressure applied on the top of the geotextile by the weight of the ballast, sleepers and track. It is not the pressure applied from above by water, which the experts agreed will pass between the graded, crushed rock aggregate, and will run off to the sides . Further, the skilled addressee, being aware of the rugged circumstances of the use as a trackbed line, would not care if small amounts of water passed through: the requirement for impermeability is not absolute. I therefore reject the Defendant's interpretation and accept what both experts agreed: in normal conditions (less than 50mm head of water), water will not pass through the geotextile from above. ..."

" the only time that water will be expelled from the subgrade is during the transit of a train, because it is the pressure of the train that actually pressurise[s] the pore water in the underlying clay in the subgrade and causes that to try to jet upwards, okay? So, the only time water will be ejected from the subgrade is during the passage of a train, which applies the pressure. So what would happen is the water that is lying in the clay, in the pores, prior to the transit, is sitting there quite happily with no pressure on it, all of a sudden a whole series of wheels comes over, putting huge pressure via the rails on to the subgrade, the immediate reaction of water is to increase in pressure and it wants to escape, and the quickest escape route is to go vertically upwards from the clay near the surface. So we get these squirts of water coming up over a period of between 5 and 10 seconds as the train passes. Once the train has passed, the pressure is gone "

Infringement

"144. both parties accepted that water will not pass through Hydrotex at a pressure corresponding to a 50mm head of water, but will pass through Hydrotex at a pressure corresponding to a 280mm head of water.

145. I do not need to resolve at exactly what head of water Hydrotex will be permeable, because the Patent claims a filtration layer which is 'normally' impermeable to water."

Hoare

i) type (a): "substantially water impermeable but provided with perforations or slits therethrough [(16)] at locations which open into the gaps between the load-spreading elements" (illustrated in Figure 2);

ii) type (b): "water vapour permeable but substantially impermeable to liquid water" (not illustrated in Hoare); or

iii) type (c): "substantially impermeable to liquid water and water vapour" (illustrated in Figure 3).

"In the case where the lower flexible sheet material is a type (b) material (i.e., water vapour permeable but substantially impermeable to liquid water), such material might be a composite sheet formed of a pair of outer water permeable textile layers with an intervening water vapour permeable barrier layer e.g. a barrier layer formed of an unsintered sheet of polytetrafluoroethylene which is expanded so as to produce a fine microstructure characterised by nodes interconnected by fibrils (see for example GB 1355373)."

Gore

Novelty

"It may be easy, given a knowledge of a later invention, to select from the general teachings of a prior art document certain conditions, and apply them to an example in that document, so as to produce an end result having all the features of the later claim. However, success in so doing does not prove that the result was inevitable. All that it demonstrates is that, given knowledge of the later invention, the earlier teaching is capable of being adapted to give the same result. Such an adaptation cannot be used to attack the novelty of a later patent."

"As I have indicated by reference to the quotation from UNION CARBIDE, it is this requirement that performance of an invention disclosed in the prior art must necessarily infringe the patent which distinguishes novelty from obviousness. If performance of an invention disclosed by the prior art would not infringe the patent but the prior art would make it obvious to a skilled person how he might make adaptations which resulted in an infringing invention, then the patent may be invalid for lack of an inventive step but not for lack of novelty."

"88. In my judgment, the Defendant's lack of novelty case fails for the following reasons:

(a) as the Claimant pointed out, the invention described in Hoare, even including the reference to Gore, does not read onto the structure described in the Patent: Hoare does not describe the use of a filter layer, nor does it reference a layer which is normally impermeable to water but allows the upwards passage of water under the load of a train. Hoare does not address these concepts at all;

(b) Hoare directs the skilled addressee to a choice of three lower layers of which the Defendant relies on type (b). This is a 3-layer sandwich construction, but Hoare directs that the middle layer must be substantially impermeable to liquid water and Professor Ingold gave no clear answer as to why the skilled addressee would ignore this requirement, even taking into account example 10 from Gore. Even so, if the skilled addressee considering Hoare wanted a water permeable layer, Hoare would direct her/him to a type (a) material with large perforations or slits in it, on which the Defendant expressly did not rely.

89. In my judgment, Hoare (incorporating Gore) does not allow the skilled person, using the CGK, to perform the invention. It does not provide clear instructions to make something that would infringe the Patent. Nor does it disclose directions which would inevitably result in the invention being performed. Rather, as Professor Ingold conceded, Hoare would not be seen as having a practical application for a commercial product. Hoare has not planted its flag at the precise destination of the Patent. Indeed, in my judgment, Hoare instructs something else."

Conclusion

Sir Nicholas Patten:

Lewison LJ: